What are the requirements for injection mold manufacturing standards?

- 1. There must be no sharp corners on the mold, which need to be chamfered. Except where specified.

- 2. The internal mold and mold parts must not be welded without consent.

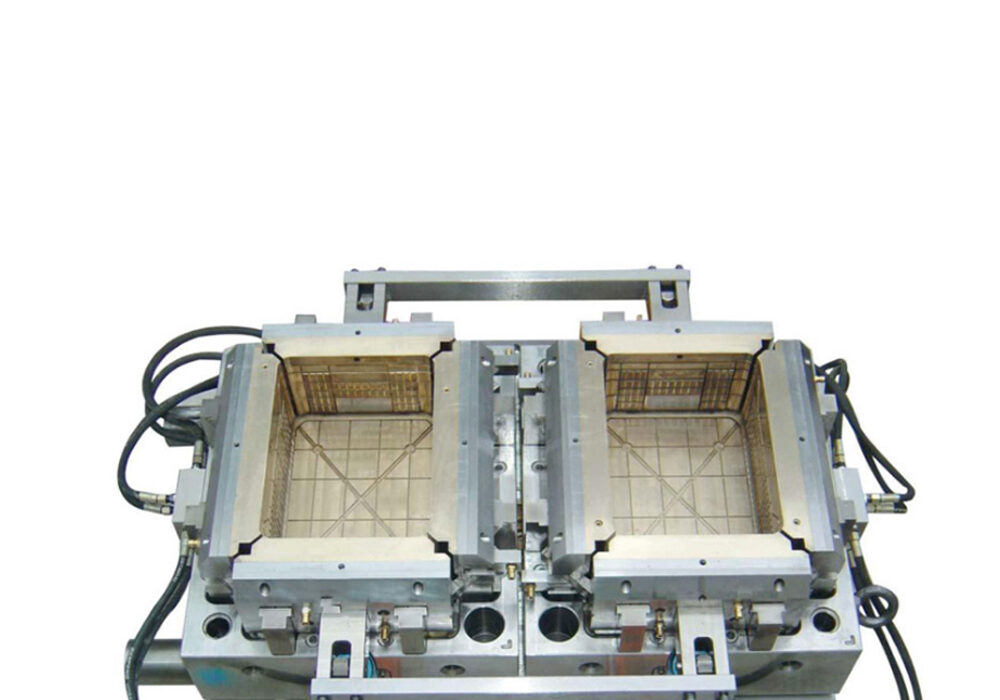

- 3. The periphery of the mold product must be vented at an appropriate location. For the specifications of the vent, please refer to the mold design manual.

- 4. The mold needs to install side locks (straight locks) on all four sides. If you cannot install the side lock, you need to install a taper lock, or a cone lock. The taper lock should be installed horizontally.

- 5. Mold handover and acceptance: It is necessary to cooperate with the mold engineer to pass the acceptance of the “mold checklist” in order to play the package and mold.

- 6. Before moving the mold, the water pressure must be tested (more than 100pa). After accepting the water, the air gun should be used to blow the water clean.

- 7. The conventional structural mold must be equipped with bracing heads. The two ends need to be flattened. The small molds are preloaded with 0,1mm, and the large molds are preloaded with 0,1mm-0,15mm.

- 8. For the mold base less than 2020, the prying mold pits need to be made between the a and b plates; all the mold bases larger than 2020, including the thimble plates, have to be pried.

- 9. Exhaust grooves should be processed on the guide bush of the mold base to prevent the guide bush from being damaged.

- 10. During the manufacturing process, the outer surface of the mold base needs to be maintained to prevent rust and scratches. Before mold packaging, the inner mold needs to be sprayed with white / or colorless rust inhibitor. All mold surfaces must be cleaned and then buttered.

- 11. The flow channel and the glue inlet need to save light # 400-600.

- 12. The surface treatment of the inner mold glue level must be carried out in accordance with the bom table or other officially notified technical requirements. The processing lines on the non-glue surface (wire cutting, milling machine, cnc gong bed, spark machine) should also use oil stone to save light.

- 13. All internal mold materials and mold blank grade requirements must be purchased based on the order or the technical requirements officially confirmed during the design review process. Material certification must be provided. If it is a hard mold, a heat treatment report and all relevant certifications must be provided.

- 14. The front and back inner molds, inserts, rows, slanted tops, straight tops (push blocks), and shovel chickens of all molds need to process a waist-shaped pit on the bottom or side to engrave the material name and hardness.

- 15. Avoid using a sander to grind the mold as much as possible. If you must use a sander to process, you must use whetstone to save light (especially the parting surface).

- 16. Rows, push blocks, shovel chickens, chisels and other important wear parts must be nitrided and hardened.

- 17. The line position must be positioned. Positioning methods include slingshot, wave bead, hasco (dme) standard line clamp, etc., specific needs according to the requirements of each project. The row position needs to have bead and wear plate. For beading and wear-resistant plates, wear-resistant hard materials must be used, and oil grooves must be added.

- 18. The oblique guide column in the row position must be compacted, and cannot be rotated or loosened. The tail of the inclined guide column must be processed into a hemispherical or truncated cone shape, which is conducive to ensuring the normal movement of the row position. If there are two or more inclined guide posts on the same row, the length, size and inclination of the inclined guide posts must be the same.

- 19. Sloping roof seats must use wear-resistant hard materials. The oil tank must be processed for the inclined roof. The inclined roof seat is generally hardened to hrc40-45 degrees with 2510 or cr12. Because the inclined roof seat is subjected to an impact load, it cannot be too hard or it will break, and chamfer the c angle at all right angle positions . A sloped top guide plate (bronze) is required. No welding is allowed.

- 20. The thimble, the cylinder, the thimble, the oblique top and the thimble plate shall be engraved with the corresponding identification codes for easy installation. If the position of the thimble is not horizontal on the product, the thimble base needs to be made into “d” type or use anti-rotation pin key positioning.

- 21. The thimble adopts the Hasco or dme standard, which one depends on the technical requirements of the mold or other officially notified mold.

- 22. For processing water-carrying aprons (“o” -shaped aprons) grooves, it is necessary to reserve a gap of 0, 25mm on one side. Generally, the aprons should be preloaded with 0, 5 ~ 0, 8mm. It can easily be damaged by pressure and cause water leakage.

- 23. The hot nozzle wire slot must be rounded to avoid scratching the wire.

- 24. Install the hot nozzle id card on the side of the mold panel.

- 25. If the nozzle is to be nitrided, it is necessary to do a stop-sale. The radius of the nozzle must meet the drawing requirements. The jaws are not nitrided and may have been bruised before the mold was moved.

- 26. The diameter of the positioning ring must conform to the drawings, and the form and position of the top rod joint must conform to the drawings.

- 27. The specifications of the water nozzle should be based on the bom table or the confirmed mold drawing. The countersinking hole of the water nozzle must be processed and installed according to the mold drawing. Drill holes must not be misaligned, and sharp angles need to be chamfered.

- 28. Water transportation must be marked with ini, outi, in2, out2 ,,,,,,

- 29. All the marks on the mold must be neat and correct, and must not be twisted.

- 30. All screws and mold parts need to be standard parts, and the screw head cannot be sawed off. The effective locking length of the screw must be sufficient, normally 1, 5 or 2.