1. Profile

Profiles refer to bars, sheets and other cross-section profiles of various cross-sections. This is the most used type of blank in mold parts. After blanking, it is sent to the processing workshop for surface processing. The main ways of cutting such materials are shearing, sawing, grinding wheel cutting, flame cutting, breaking, etc

2. Forging

Forgings are blanks with reasonable geometry and size obtained by forging the profile. Forging mainly includes axial upsetting, horizontal upsetting and multi-directional upsetting. The purpose of forging is to obtain a reasonable geometry and machining allowance, save raw materials and reduce the amount of machining. Improve the condition of the metal structure, so that the looseness and bubbles are improved, and the density can be increased. Improve the direction of metal fibers in the blank, make its distribution more reasonable, and improve the bearing capacity and performance of the parts. Improve the unreasonable distribution of carbides in the material, and improve to know the heat treatment performance, mechanical processing performance and mold life.

3. Casting

Castings commonly used in plastic molds are steel castings, cast irons, aluminum castings, etc. The shape and size of the casting should meet the requirements of the casting drawing, and its chemical composition and mechanical properties should meet the specified requirements. The surface of the casting should be sand-cleaned, and the scars, flashes and burrs should be removed, and the residual height should not be greater than 3mm. There should be no defects such as pores, sand holes, cracks, etc. inside the casting, especially near the working surface, and no serious looseness and large shrinkage holes in the non-working surface. The castings should be heat-treated in time, the steel castings should be fully annealed, and the cast irons should be aged to eliminate internal stress and improve processing performance.

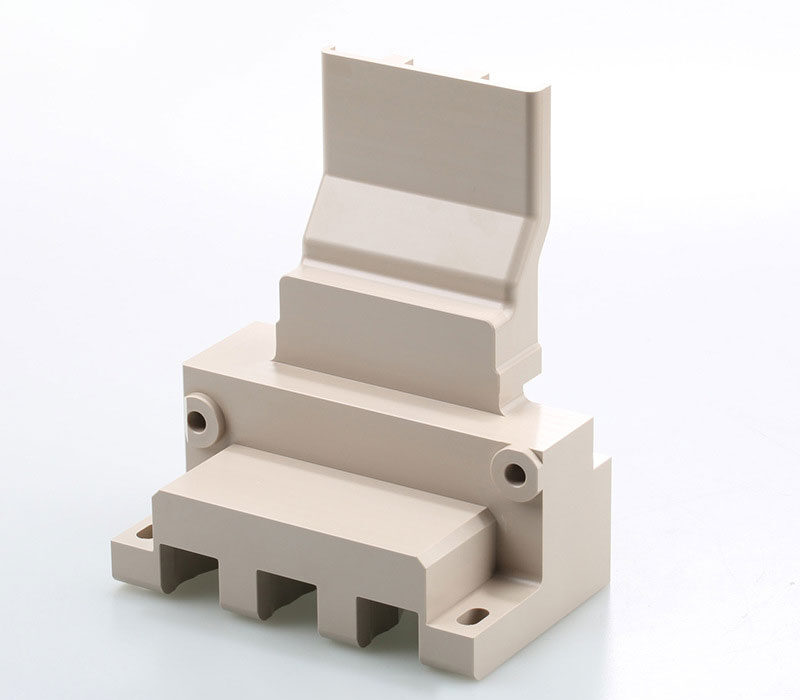

4. Mold standard parts

With the development of mold specialization, parts such as mold frames and templates appearing in the form of commodities are increasing. After using these mold standard parts, only the molding surface and related parts can be processed, which greatly shortens the mold manufacturing cycle. With the development of mold technology, plastic mold standard parts will be the mainstream direction of mold part blanks.