Among the four elements of quality, delivery cycle, price and service of plastic mold, more and more users have put the delivery cycle in the first place. Demanding mold companies to deliver as soon as possible has become a trend. Enterprises do everything possible to improve their adaptability, improve technical level, improve equipment level, improve management level and improve efficiency, etc. are all effective means to shorten the mold production cycle.

Vigorously improve the development ability, push forward the development work as far as possible, until it is involved in the product development of the mold user, and even develop before the user object is clear, and become passive to active. At present, this method has been adopted in TV and display housings, air conditioner housings, motorcycle plastic parts, etc., and mobile phone and telephone mold development has also begun to try. This approach breaks the long-standing passive situation in which the mold factory can only wait for a contract to design the mold according to user requirements.

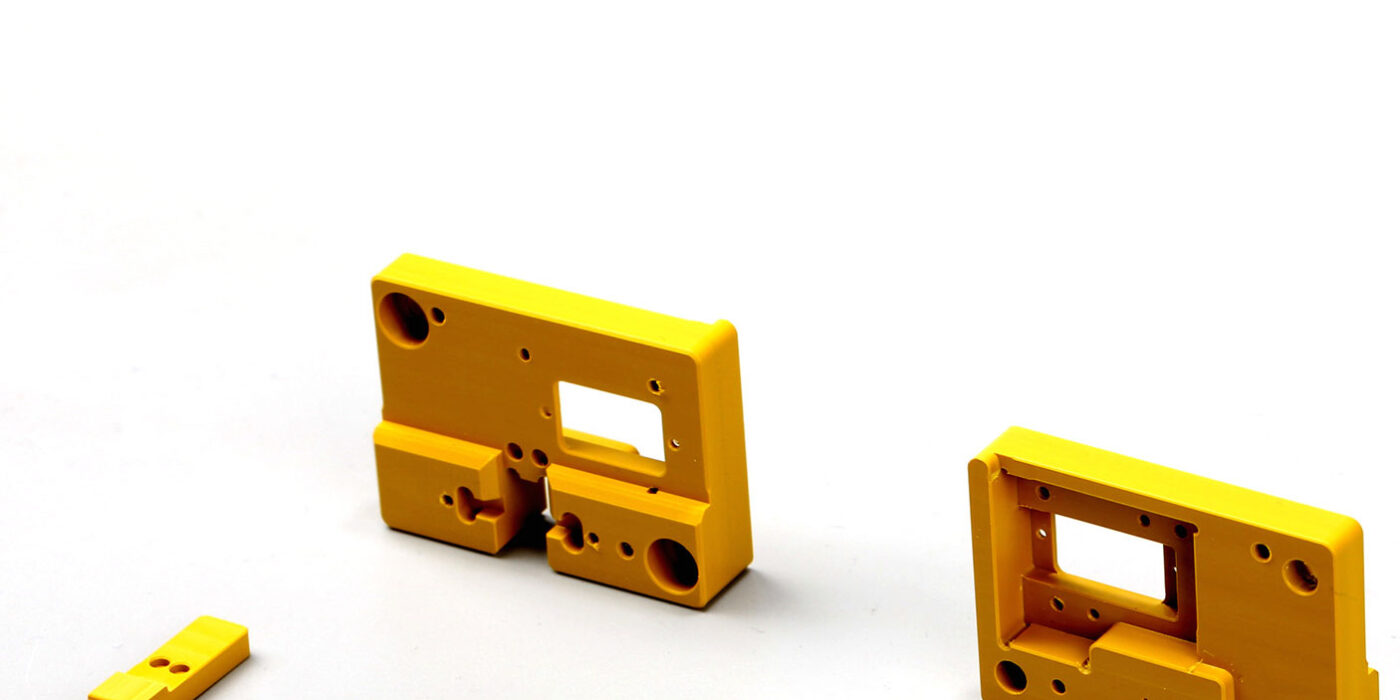

With the improvement of the design and processing level of mold enterprises, the manufacture of molds is changing from relying mainly on the skills of fitters to relying mainly on technology. This is not only a change in production methods, but also a change in production methods and a rise in concepts. This trend has led to the continuous improvement of the standardization of molds, the precision of molds is getting higher and higher, the production cycle is getting shorter and shorter, and the proportion of fitters is getting lower and lower, which ultimately promotes the continuous improvement of the overall level of the mold industry. China’s mold industry currently has more than 10 national high-tech enterprises, and about 200 provincial and municipal high-tech enterprises. In line with this trend, the gradual transformation of the main backbone of mold production from technical talents to technical talents is an inevitable requirement. Of course, at present and for a long period of time, skilled talents are still very important, because after all, it is difficult for molds to completely get rid of relying on skills.

Mould companies and their mold production are rapidly developing towards informatization. In the information society, as a high-level modern mold enterprise, the application of CAD / CAM alone is no longer enough. At present, many enterprises have adopted technologies such as CAE, CAT, PDM, CAPP, KBE, KBS, RE, CIMS, ERP and other advanced manufacturing technologies and virtual network technologies, which are all manifestations of informatization. The trend towards informationization has become an industry consensus.

It is not only the plastic industry that needs innovation, including industries such as electronic and electrical waste treatment, solid waste recycling, scrapped car recycling, and waste paper recycling, which all need to improve their independent innovation capabilities. It is not enough to improve the internal power of itself, but also insist on using development methods to solve the problems in progress, change the new development mode, cater to the trend, rely on innovation-driven development, develop in the direction of informatization, and accelerate the steady progress of the industry.