In the mold design process, you need to consider what factors affect its structure and mold system, understand the basic elements, and make adequate preparations under the premise of design.

- 1. Cavity layout. Determine the number and arrangement of cavities according to the geometric structure characteristics of plastic parts, dimensional accuracy requirements, batch size, mold manufacturing difficulty, mold cost, etc.

- For injection molds, the precision of plastic parts is 3 and 3a, the weight is 5 grams, a hardening pouring system is used, and the number of cavities is 4-6; the general precision of plastic parts (4-5 grade) The material is partially crystalline material, the number of cavity can be 16-20; the weight of plastic parts is 12-16 grams, the number of cavity is 8-12; and the weight of plastic parts 50-50 grams, the number of cavity is taken 4-8. For amorphous plastic parts, the recommended number of cavities is 24-48, 16-32 and 6-10. When we continue to increase the weight of plastic parts, multi-cavity molds are rarely used. For plastic parts with 7-9 precision, the maximum number of cavities is increased to 50% compared with the plastics with 4-5 precision.

- 2. Determine the parting surface. The position of the parting surface should be conducive to mold processing, exhaust, demolding and forming operations, surface quality of plastic parts, etc.

- 3. Determine the pouring system (the shape, position and size of the main runner, sub-runner and gate) and the exhaust system (exhaust method, exhaust slot position and size).

- 4. Select the ejection method (ejection rod, ejector tube, push plate, combined ejection), determine the method of undercut treatment, core pulling method.

- 5. Decide the cooling and heating method and the shape and position of the heating and cooling groove, and the installation location of the heating element.

- 6. According to the mold material, strength calculation or empirical data, determine the thickness and external dimensions of the mold parts, the external structure and the location of all connections, positioning and guides.

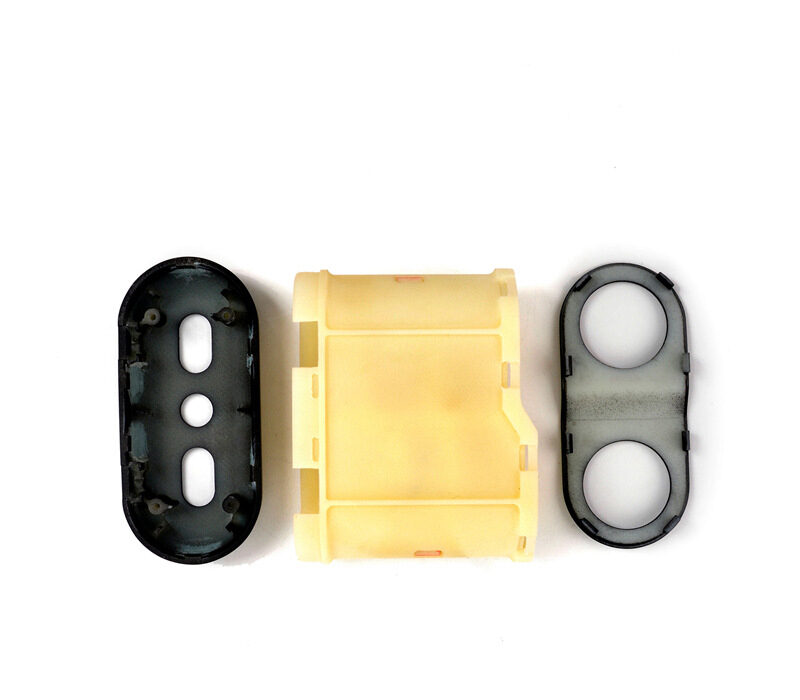

- 7. Determine the structure of the main molded parts and structural parts.