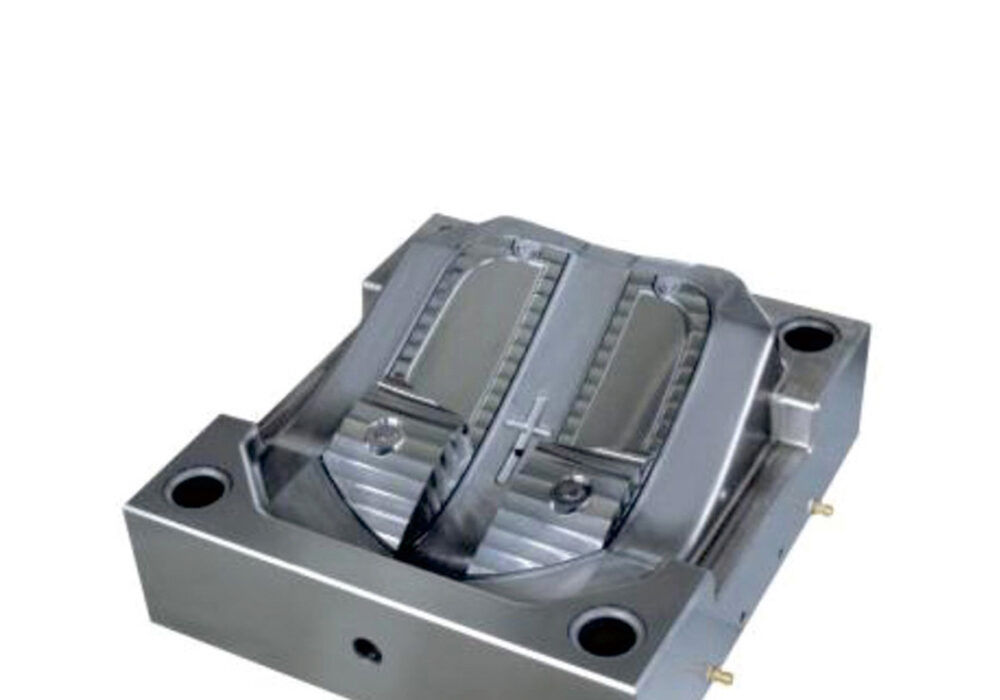

How to take the stubborn finished product left in the mold

- 1. Use brass sheet to squeeze hard into the crack between the finished product and the mold, pry the finished product out of the mold cavity, but apply this method to the non-ferrous alloy mold.

- 2. In order to achieve this purpose, a brass sheet should be prepared on the injection molding machine (for example, a brass sheet with a thickness of 3MM, a width of 300MM, and a front end molded into a knife shape)

The development and application of new mold technology is the direction

New mold technology, the development and application of new mold technology is the direction of future development. According to information, the development and application of new mold technology will become the key direction of the domestic mold production industry in the future. The high-end doorway of China’s automobile molds is the only way for mold companies to develop. The needs and development of the market also promote the large-scale multi-station progressive die supporting other large and medium-sized stamping parts. According to inquiries, the research and development and application of new mold technology will become the focus of the domestic mold production industry in the future. The high-end doorway of China’s automotive mold is the only way for mold companies to develop, the city …

3. Replacement with a screwdriver will cause serious damage to the mold.

4. For the finished product that can neither be cut nor cracked, use the brass piece mentioned above to simply tap it into the finished product with a hammer, but this may make the surface of the cavity concave, so that it can only be on the surface of the finished product and the mold The surface is cracked, do not touch the surface of the mold cavity.

5. In order to cut off the finished product, there is also a way to simply use a torch to heat, which is only effective for large places. But pay attention to the need to stay away from combustible materials. For small places, you can use “35 point 4 of the method of taking out the material left in the spout” to get it.

6. If there is a small piece of finished product that cannot be taken out, apply a solvent of this material (such as acetone, etc.) to the top. After dissolving, knock it out with a brass rod, but pay attention to the solvent not to be close to the fire.

7. Remove the surface of the residual cavity of the finished product, clean it with a cloth and spray with a release agent. However, it should be noted that the release agent has an effect on the secondary processing (coating, welding, etc.) of the finished product, and it should be dignified when used.

Overall mold planning, large-scale composite material wind power blade mold overall planning and production technology

Overall mold plan, large-scale composite material wind power blade mold overall plan and production technology Composite material wind power blades are the components of energy conversion in wind turbines. The quality of their planned production is related to the compliance and service life of wind turbines, which affects The function of the whole system. The quality of the blade molding depends on the quality of the mold. The high-precision mold planning and production technology is a tight guarantee for the aerodynamic shape of the blade, which is determined to make the product obey, the ultimate quality and function. As the wind turbines continue to expand in size, the size of wind turbine blades gradually increases …