The injection mold is a tool for producing plastic products; during the processing of the injection mold, the plastic melted by the heat is injected into the mold cavity by the injection molding machine at high pressure, and after cooling and solidification, the molded product is obtained. So what are the characteristics of injection mold processing?

- 1. Off-site design and off-site processing. Mold processing is not the final goal, but the final product design is proposed by the user. The mold processing manufacturer designs and processes the mold according to the user’s requirements. In all cases, the injection of products is also produced by other manufacturers. This has caused the situation of product design, mold design and processing and production of products in different places.

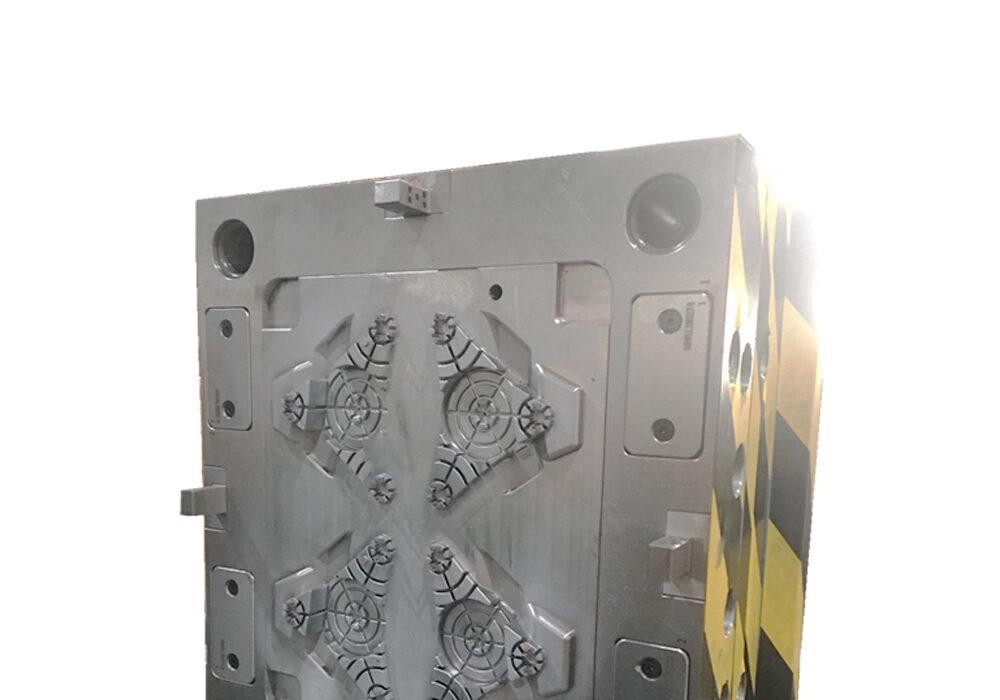

- 2. The cavity and core are three-dimensional. The external and internal shapes of the plastic parts are directly formed by the cavity and the core. The processing of these complex three-dimensional surfaces is more difficult. The special processing of the cavity is the blind hole internal molding. If the traditional processing method is adopted , Not only requires workers to have a high level of craftsmanship, more auxiliary fixtures, more tools, but also a long processing cycle.

- 3. Long process flow and tight processing time. As far as injection molded parts are concerned, most of them are combined with other parts to form a complete product, and in many cases, other parts have been completed. Kong Yin looks forward to the market for injection molded parts. Because of the high requirements on the shape or dimensional accuracy of the products, and because of the different characteristics of the resin materials, after the mold processing is completed, it is necessary to frequently test and modify the mold, which makes the development and delivery very serious.

- 4. High precision and general quality requirements and long service life requirements. At present, the dimensional accuracy of general plastic parts is IT6-7, and the roughness of the profile is Ra0.2-0.1μm. The response of the dimensional accuracy of the injection mold parts is IT5-6, and the roughness of the profile is less than Ra0.1μm. The roughness of the real surface of the laser disk should reach 0.02-0.01μm of the level of mirror processing, which requires the roughness of the mold profile to be less than 0.01μm. Long-life injection molds are very necessary to advance high efficiency and reduce costs. The service life of injection molds today generally requires more than 1 million times. Cautious injection molds use a rigid mold frame, increase the thickness of the template, add support columns or tapered positioning elements to prevent the mold from deforming after being pressed, and sometimes the internal pressure can reach 100MPa. The ejection assembly is the main identity that affects the deformation and dimensional accuracy of the product, so the best ejection point should be selected to make the demolding average over the ground. High-precision injection molds are inlaid or fully assembled in structure, which requires the processing accuracy and exchangeability of mold parts to advance.

- 5. Professional division of labor, dynamic combination. The production volume of the mold is small, generally belongs to the production of a single piece, but the mold requires a lot of standard parts, from the mold frame to the thimble, these cannot be completed by only one manufacturer, and the processing technology is complex and popular equipment And the use of CNC equipment is extremely unbalanced.