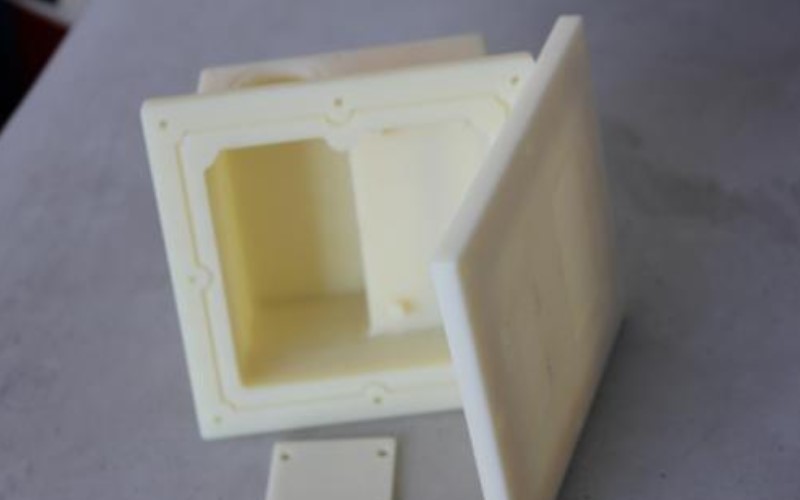

The injection mold is a tool for producing plastic products; it is also a tool for giving plastic products a complete structure and precise dimensions. Injection molding is a processing method used in mass production of certain shapes and complex parts. Specifically, the plastic melted by heat is injected into the mold cavity by a high-pressure injection molding machine, and after cooling and solidification, a molded product is obtained. What are the advantages of plastic products formed by injection molds.

What are the advantages of injection molded products?

- 1. The operation is easy to master and does not require higher-level technical operations.

- 2. Injection can generally be formed at one time, reducing the processing procedures of products.

- 3. Plastic products with more complicated shapes can be produced.

- 4. The waste products and waste materials after injection molding can be re-injected hotter, so materials are saved.

- 5. The mold is simple and general, and the finished product is low.

- 6. The injection molding process can be completed by a machine tool automatically according to a certain program, which is convenient for automation and improved production efficiency, suitable for mass production.

Dongguan injection mold factory ptj precision is a professional one-stop injection mold manufacturer of injection mold and two-color mold opening, injection and spraying. It has 9 imported CNC equipment, including Taiwan Dali CNC, Japan FANUC, Japan Sodick mirror spark machine; has 19 two-color injection molding machines, 25 single-color injection molding machines, including 9 Japanese Nissei injection molding machines, 21 Haitian injection molding machines; Swedish ternary / secondary detectors and other equipment, and the introduction of Xinliguang 320 Misan Tu and Sanba automatic spraying line and 10,000-level dust-free workshop ensure that the precision of the mold is within ± 0.002mm and the product quality, so that customers are satisfied.