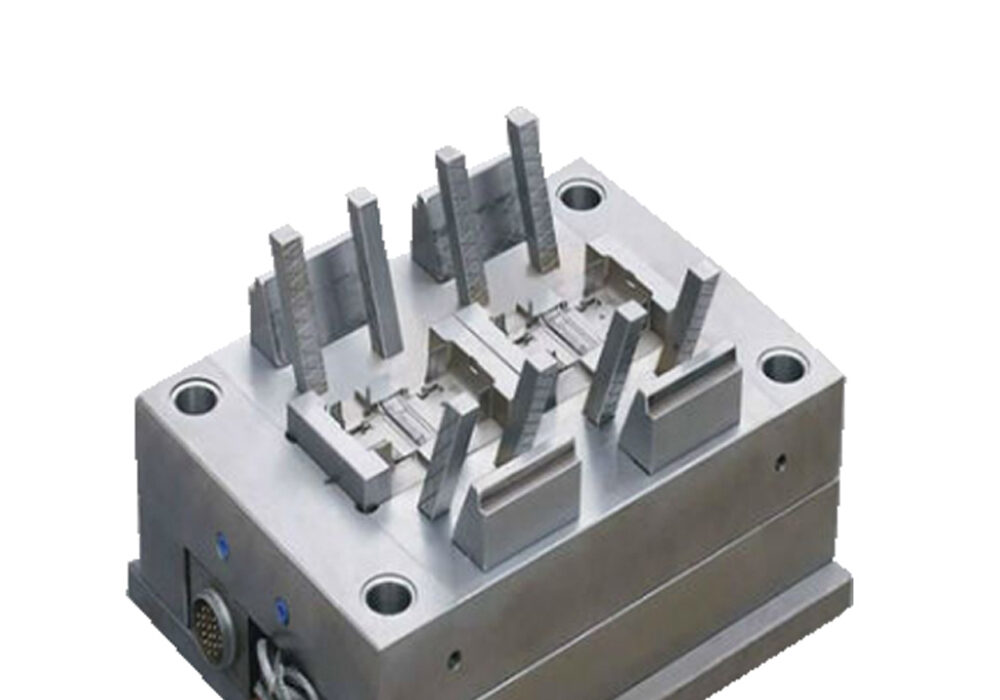

Dongguan Injection Mould Factory PTJ was established in 2006 and has 11 years of experience in two-color mold injection processing. There are more than 500 employees and 15,000 square meters of workshops, including more than 70 mold technicians and 35 quality control personnel. Precision CNC machining center, slow wire cutting, EDM mirror spark machine, high-speed high-precision injection molding machine, three-dimensional, two-dimensional measuring instruments and other important mold processing, production, testing and other necessary equipment.

PTJ Dongguan injection mold manufacturers imported 11 CNC machines, 11 spark machines, 3 slow wire, 9 grinders, 3 milling machines, 51 injection molding machines: 19 injection mold machines, including 12 250 tons or more , 7 sets under 100 tons; 32 single-color injection molding machines, including 5 sets of 360 tons, 12 sets between 250 tons and 300 tons, and 15 sets below 180 tons; 10,000-class oil-injected dust-free workshop, introducing new power Light 320 meters automatic injection line.

The strength of PTJ personnel and equipment in Dongguan injection mold manufacturers guarantee the possibility of mass production of mold products and the service life of molds, as well as the quality of mold products.

PTJ specializes in one-stop service of injection mold manufacturing, mold opening, injection molding, spraying and assembly. It does not require your factory to run, and implements strict quality control procedures, starting from the mold raw materials to the final delivery They are strictly controlled to ensure that the rationality of the two-color mold design, manufacturing accuracy, mold life and quality of injection products meet your requirements, and produce high-quality molds and mold injection products for you.

PTJ knows that quality is the basis of survival, so it will conduct a three-dimensional inspection of Tong Gong and Mo Ren. PTJ Dongguan injection mold manufacturers can provide customers with the following services:

- 1. Design and development of single and double color molds;

- 2. Single and double color mold injection;

- 3. Three-coat three-roast automatic injection line;

- 4. Assembly and packaging;

- 5. Professional transportation fleet escorts customers’ products