Open mold injection molding is a processing method used for mass production of certain shapes and complex parts. The specific principle is as follows: the plastic material heated and melted is injected into the cavity of the plastic mold from the screw of the injection molding machine, and the plastic molded product is obtained after cooling and solidification.

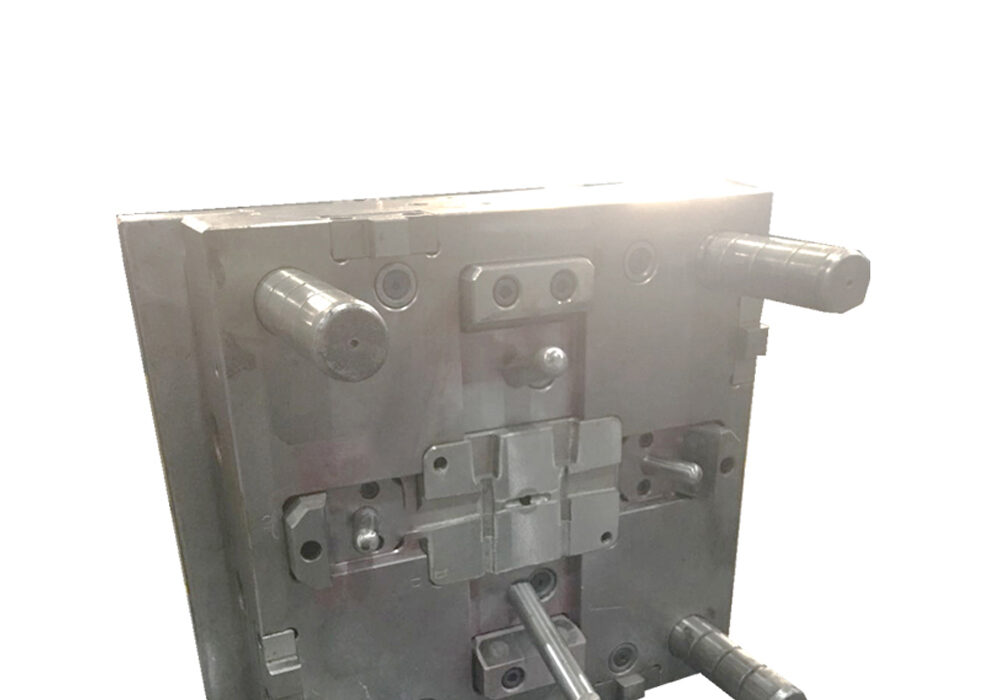

Plastic mold consists of two parts: movable mold and fixed mold. The movable mold is installed on the movable template of the injection molding machine, and the fixed mold is installed on the fixed template of the injection molding machine. In injection molding, the movable mold and the fixed mold are closed to form the pouring system and the cavity. When the mold is opened, the movable mold and the fixed mold are separated to take out the plastic products.

Five elements of the injection molding process:

1. Temperature

- a. Oil temperature: For hydraulic machines, it is the heat energy generated by the frictional movement of hydraulic oil. It is controlled by cooling water. When starting the machine, the oil temperature must be around 45 ° C. If the oil temperature is too high. Or too low will affect the transmission of pressure.

- b.Material temperature: the temperature of the barrel. The temperature should be set according to the shape and function of the material and product. If there are files, please set according to the files.

- c. Mold temperature: This temperature is also an important parameter. Its height has a great influence on the performance of the product. Therefore, the function and structure of the product must be considered when setting, as well as the material and cycle.

2. Speed

- a. Speed setting of the opening and closing mode, the setting of the opening and closing mode is generally based on the principle of slow-fast-slow, so the setting mainly considers the machine, mold and cycle.

- b. Ejection setting: can be set according to product structure. It is best to use a slow speed to eject part of the structure and use it to quickly demold and shorten the cycle.

- c. Burning rate: According to the size of the product, the structure should be shaped. If the structure is more complex and thinner, it can be shaped quickly. If the structure is simple, the wall thickness can be used slowly. It can also be set from slow to fast according to the performance of the material.

3. Pressure:

- a. Injection pressure: According to product size and wall thickness from low to high, other factors should be considered during commissioning.

- b. Packing: Packing is mainly to ensure the shape and size of the product is stable, and set according to the structure and shape of the product.

- c. Low pressure protection pressure: This pressure mainly protects the mold and minimizes mold damage.

- d. Clamping force: refers to the force required by the mold to clamp high pressure. Some machines can adjust the clamping force, while others cannot.

4. Time

- a. Glue injection time: The set value of this time must be greater than the actual time, and can play the role of glue injection protection. The setting value of the shooting timing is larger than the actual value by about 0.2 seconds. The setting should consider the coordination of pressure, speed and temperature.

- b. Low voltage protection time: In this manual state, first set the time to 2 seconds, and then increase about 0.02 seconds according to the actual time.

- c. Cooling time: This time is generally set according to the size and thickness of the product, but the melting time should not be greater than the cooling time, so that the product can be fully formed.

- d. Holding time: This time is to ensure the size of the product after the injection is completed. The time for cooling the gate before the mold opening injection gate is inverted under the holding pressure can be set according to the gate size.