Compared with other mechanical processing, plastic mold processing has its own special characteristics, so there are certain requirements for mold processing equipment.

The plastic mold processing equipment proposes the following basic requirements:

The machine tool must have good rigidity and a large load capacity that is compatible with the weight of the module;

The size of the work surface should be compatible with the shape of the mold. It is suitable for rectangles, squares and circles, not narrow and long, but it requires a large space in the height direction and its stroke; it must have high accuracy and accuracy retention

To be able to remove the margin quickly and efficiently, and have a high reliability, to maintain continuous long-term full-load operation;

In order to adapt to complex space curved surface processing, and there is a large amount of processing, it is required that the machine tool can be multi-axis linkage, and equipped with a large information capacity CNC system.

Of course, the above only mentions some basic requirements for the processing of most plastic molds, and there are still many special requirements. For example, machine tools for processing plastics require higher speeds, but due to the small cutting force, in order to reduce costs, the machine tool can use a lightweight structure; the press for trial molds does not require high efficiency and speed, but it requires reverse rotation In order to repair the mold; a large number of repetitive processing of some simple processes can be used for special machines, etc. At the same time, composite processing, flexible processing and online inspection are also requirements for mold processing.

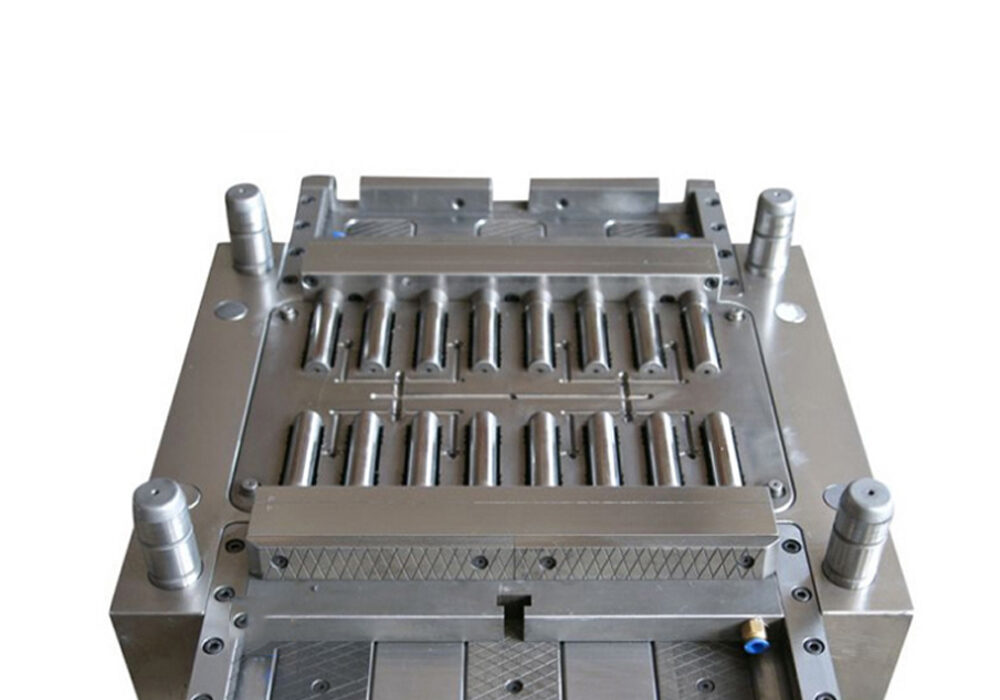

Injection molding is the most commonly used method in plastic mold plastic processing. This method is applicable to all thermoplastics and some thermosetting plastics. The quantity of plastic products made is unmatched by other molding methods. As one of the main tools of injection molding processing, injection molds have high quality accuracy, manufacturing cycle and injection molding process. The level of production efficiency in China directly affects the quality, output, cost and product update of the product, and also determines the company’s ability and speed in the market competition.

The plastic injection mold is composed of several steel plates and various parts, which are basically divided into: A forming device (female die, punch die) B positioning device (guide post, guide sleeve) C fixing device (I-shaped board, code die pit ) D Cooling system (water transport hole) E Constant temperature system (heating tube, heating wire) F Runner system (chirp hole, runner groove, runner hole) G Ejection system (thimble, ejector)