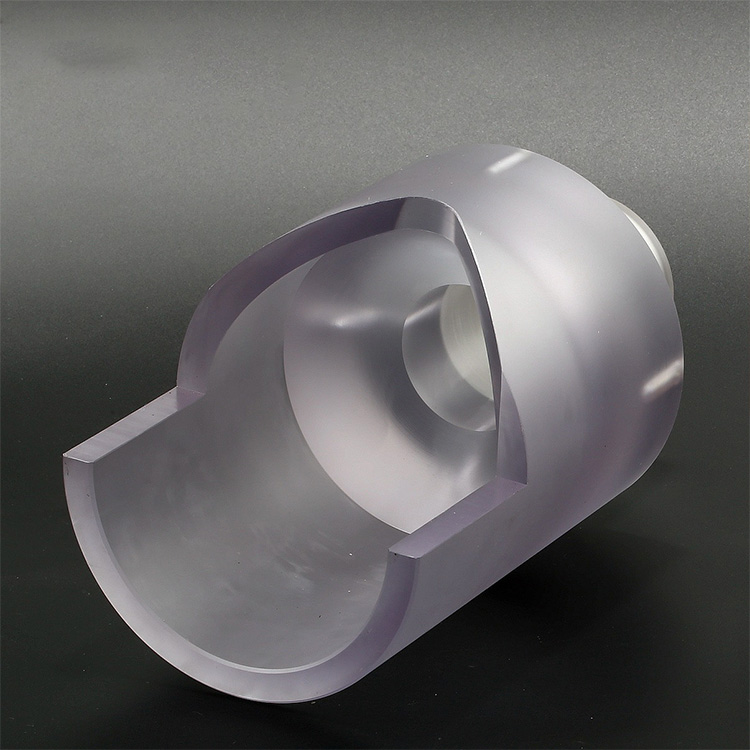

Requirements for the selection of mold materials

(1) The mold meets the requirements of working conditions 1. Wear resistance When the blank is plastically deformed in the mold cavity, it flows and slides along the surface of the cavity, causing severe friction between the surface of the...