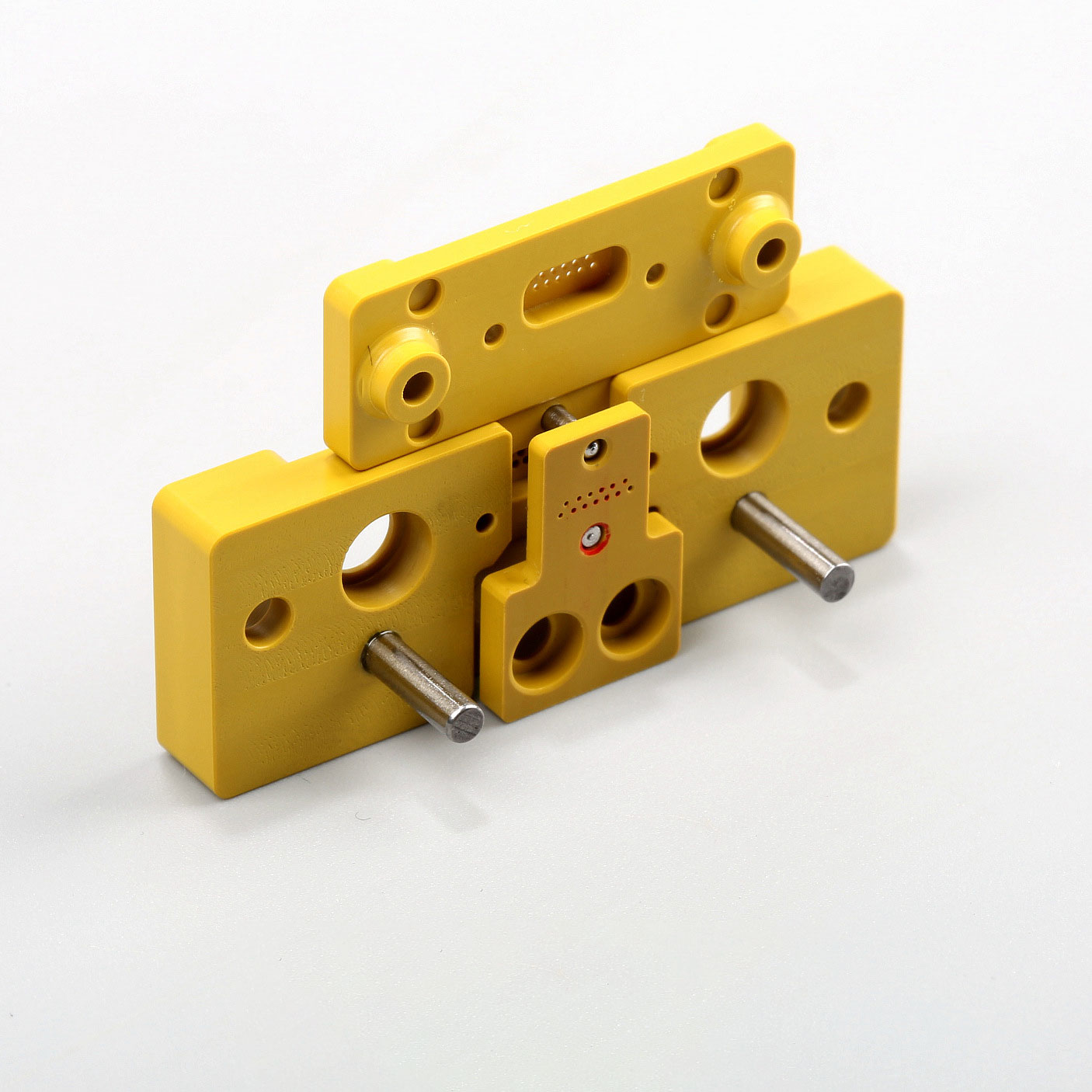

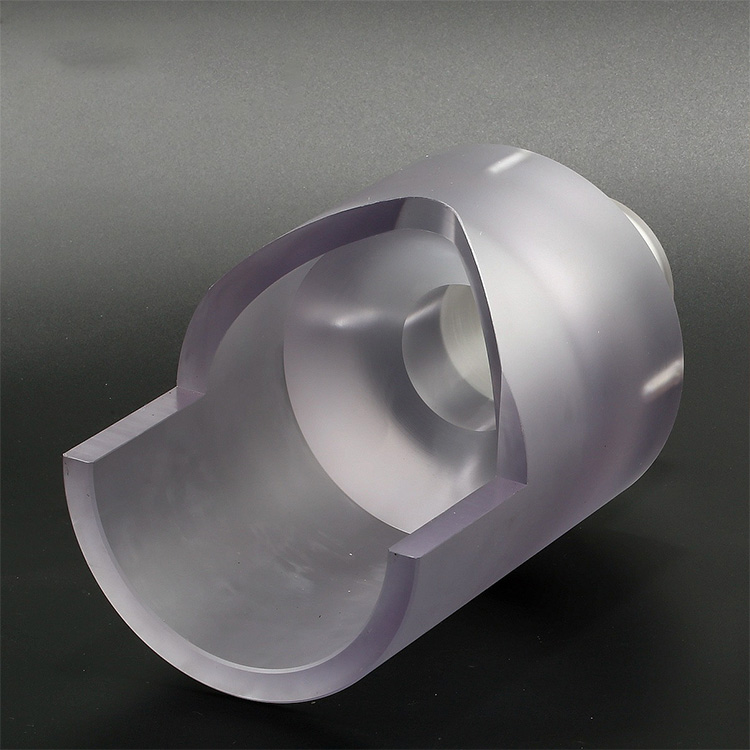

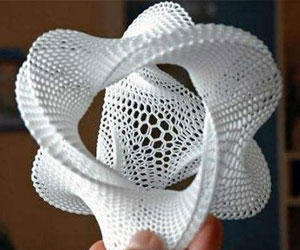

The plastic mold trade deficit is increasing year by year

Although the increase in the export of plastic molds is greater than the increase in imports in recent years, the absolute increase is still that imports are greater than exports, resulting in an increase in the mold trade deficit year...