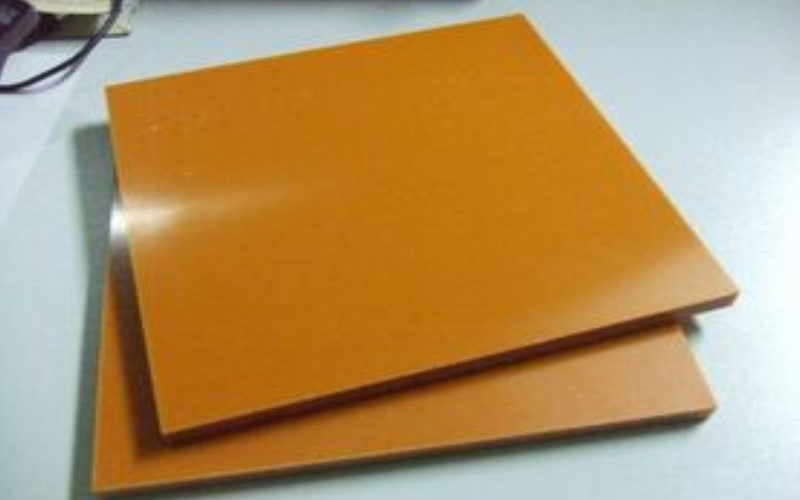

Modified Phenolic Resin

The purpose of bakelite phenolic resin modification is mainly to improve its brittleness or other physical properties, improve its adhesion to fiber-reinforced materials and improve the molding process conditions of composite materials. Modification is generally through the following channels: ① Block...