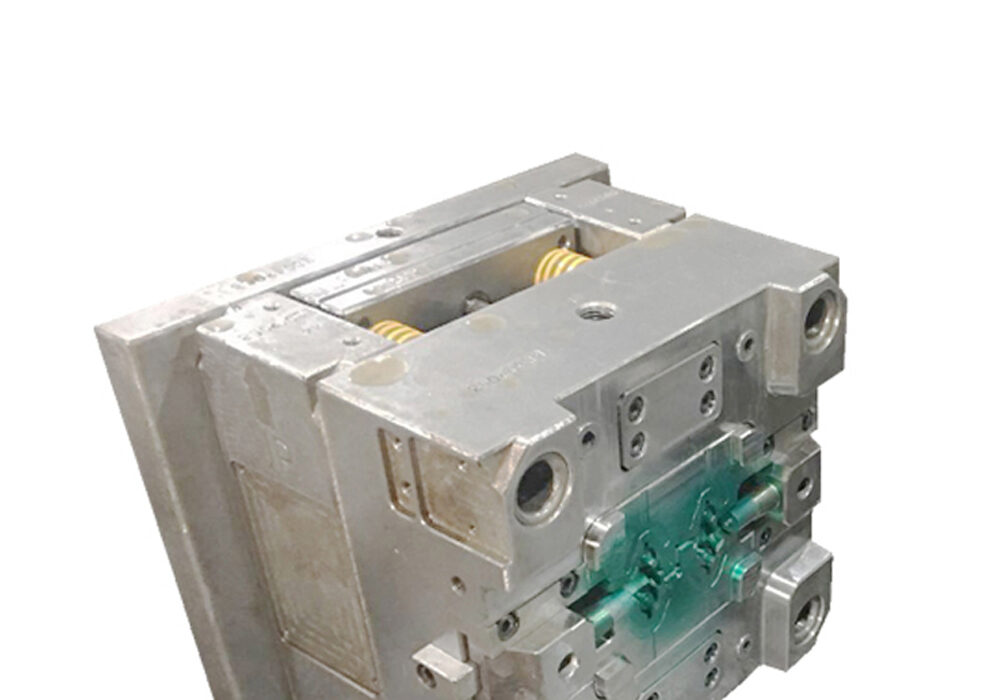

The injection mold is a tool for producing plastic products, and is a tool for making plastic products complete in structure and accurate in size.

The injection mold consists of two parts: movable mold and fixed mold. The movable mold is installed on the movable template of the injection molding machine, and the fixed mold is installed on the fixed template of the injection molding machine. In injection molding manufacturers, the closing of the movable mold and the fixed mold constitutes the pouring system and the cavity. When the mold is opened, the movable mold and the fixed mold are separated to take out the plastic products. In order to reduce heavy mold design and manufacturing workload, most injection molds use standard mold bases. The following are the 18 basic knowledge that injection mold must master. See which one is missing.

- 01 nozzle:The melt usually flows from the nozzle into the nozzle, but for some molds, the nozzle is part of the mold because it extends to the bottom of the mold. There are two main types of nozzles: open nozzles and closed nozzles. In injection molding, open nozzles should be used more because they cost less and are unlikely to stay.If the injection molding machine is equipped with a decompression device, the nozzle can be used even if a lower viscosity melt is used. Sometimes it is necessary to use a closed nozzle, which acts as a shut-off valve, blocking the plastic cover in the shot blasting cylinder. Make sure the nozzle is properly inserted into the nozzle sleeve. The top hole is slightly smaller than the nozzle sleeve, which makes it easier to remove the nozzle from the mold. The hole of the nozzle sleeve is 1mm larger than the nozzle hole, that is, the nozzle radius is 0.5mm thinner than the nozzle sleeve radius.

- 02 Filter and combined nozzle:The impurities in the plastic can be removed through the filter of the retractable nozzle, that is, the melt and the plastic flow through a channel, which is divided into narrow spaces by the insert. These narrow gaps can remove impurities and improve the mixing of plastics. Therefore, to expand it, a fixed mixer can be used to achieve a better mixing effect. These devices can be installed between the spout and the nozzle to separate and remix the melt, mainly to allow the melt to flow through the stainless steel channel.

- 03 exhaust:In the injection molding process of plastic mold manufacturers, some plastics need to be vented in the injection box to allow the gas to escape. In most cases, these gases are just air, but they may be molten moisture or single molecule gases. If these gases are not released, the gas will be compressed by the melt and brought into the mold, and the mold will expand and form bubbles in the product. To discharge the gas before it reaches the nozzle or mold, reduce or reduce the diameter of the root of the thread to decompress the melt in the cylinder.

Here, the gas can be discharged from the hole or the hole of the shooting tank. Then, the diameter of the screw root increases, and the melt of volatiles is directed to the nozzle. The injection molding machine equipped with this equipment is called exhaust type injection molding machine. Above the vented injection molding machine, there should be a good smoke ejector for flammable burners to remove potentially harmful gases. - 04 Increase the effect of back pressure:In order to obtain a high-quality melt, the plastic is heated or melted uniformly and mixed thoroughly. Use a suitable screw to properly melt and mix, and have sufficient pressure (or back pressure) in the shot tank to achieve mixing and thermal consistency.

Increasing the oil return resistance will create back pressure in the combustion tank. However, the screw reset time is longer, so the injection molding machine drive system wears more. Keep back pressure as far as possible, isolate from air, and require the same temperature and mixing level - 05 Globe Valve:No matter what type of screw is used, the tip is usually equipped with a globe valve. In order to prevent the plastic from flowing out of the nozzle, a decompression (rewind) device or special nozzle is also provided. If you use cut-off production and supply, you must check regularly, because it is an important part of the shooting tank. At present, switch-type nozzles are not commonly used because switch-type nozzles are prone to plastic leakage and failure. Currently, each plastic has a suitable nozzle type.

- 06 spiral backward (rewind):Many injection molding machines are equipped with screw retraction or suction devices. When the screw stops rotating, the plastic head of the nozzle is pumped back hydraulically. This device allows the use of open nozzles. The number of inhalations may be reduced, because entering the air can cause problems with certain plastics.

- 07 Screw pad:In most injection molding cycles, it is necessary to adjust the rotation amount of the screw village, so that most of the soft plastic will remain when the screw is injected, thereby ensuring that the screw reaches an effective advancement time and maintains a fixed combustion pressure. The size of the small injection molding machine is about 3mm; the size of the large injection molding machine is 9mm. No matter how many spiral fill values are used, they must remain the same. The size of the screw pad can now be controlled within 0.11 mm.

- 08 screw speed:The rotation speed of the screw has a great influence on the stability of the injection molding process and the heat acting on the plastic. The faster the screw rotates, the higher the temperature. When the screw rotates at high speed, the friction (shear) transmitted to the plastic can improve the plasticization efficiency, but it also increases the non-uniformity of the melt temperature. Due to the importance of the surface speed of the screw, for smaller injection molding machines, the rotation speed of the screw of the large injection molding machine should be smaller, because at the same rotation speed, the shear heat generated by the large screw is much higher than that of the small screw. Due to different plastics, the screw rotation speed is also different.

- 09 shots:Evaluation of syringe pressure is usually based on the amount of ps that can be injected per injection and can be measured in ounces or grams. Another classification system is based on the volume of melt that the injection molding machine can inject.

- 10 Plasticizing ability:The evaluation of injection molding machines is usually based on the amount of polystyrene that can be uniformly melted or heated to a uniform melting temperature (units: pounds and kilograms) within 1 hour. This is called plasticizing ability.

- 11 Plasticizing capacity estimation:In order to determine whether the product quality can be maintained throughout the production process, a simple yield and plasticizing capacity formula can be used, as follows: t = (total injection volume gx3600) ÷ (plastic injection molding machine kg / hx1000) t is the lowest Cycle time. If the cycle time of the mold is lower than the t value, the injection molding machine cannot sufficiently plasticize the plastic to obtain a uniform melt viscosity, so the injection molded parts often have deviations. Especially when paying attention to the injection molding of thin-walled or precision tolerance products, the amount of projectile and the amount of plasticization must match.

- 12 rounds cylinder holding time:The decomposition of plastics is based on temperature and time. For example, plastics will decompose after being placed under high temperature for a period of time; however, under low temperature environment, decomposition will take longer. Therefore, the residence time of plastic in the shooting tank is very important.

The actual residence time can be determined by experiment. The method is to measure the time required for the colored plastic to pass through the shooting box. The following formula can be roughly calculated: t = (nominal volume of the water jet tank gx cycle time s) ÷ amount gx300) Please note that some plastics stay in the water jet tank longer than the time required for calculation, because they will be in the water jet tank Accumulate. - 13 Calculate residence time and importance:In general, the residence time of plastic on a particular injection molding machine should be calculated. Plastic molds, especially large injection molding machines, use less shot peening material, and the plastic is easily decomposed, which is not observed. If the residence time is short, the plasticization of the plastic is uneven; the residence time will be weakened due to the performance of the plastic.

Therefore, it is necessary to maintain the same residence time. Method: Make sure that the plastic composition input by the injection molding machine is stable, consistent in size and shape. Any abnormal or missing parts of the injection molding machine must be reported to the maintenance department. - 14 shooting tank temperature environment:It should be noted that the melt temperature is important, and the temperature of any steel shot barrel used is only indicative. If you have not experienced the processing of special plastics, please start with the lowest setting. Usually, the temperature in the first zone is set to the lowest value to prevent premature melting and clogging of the plastic at the feed port.

Then, the temperature in other areas gradually increases until the nozzle is reached, and the temperature at the tip of the nozzle tends to be slightly lower to prevent dripping. The mold is also heated and cooled. Due to the size relationship of many molds, the molds are also different, but unless otherwise stated, each area should be set to the same size. - 15 Melt temperature:The nozzle can be measured with an air jet. When using the latter for measurement, care must be taken to ensure that the hot melt plastic is clean and correct, because the hot melt plastic can burn or even corrode the skin. In the injection molding workshop, burns were unexpected.

Therefore, when handling splashes of thermoplastics or hot melt plastics, gloves and masks should be worn. To ensure safety, the tip of the thermal control needle should be preheated to the temperature to be measured. Each plastic has a specific melting temperature. In order to achieve this temperature, the actual fuel injection cylinder adjustment value depends on the speed, back pressure, shot volume and injection cycle of the screw cylinder. - 16 Mold temperature:Be sure to check whether the injection molding machine settings and operating temperature meet the requirements of the record sheet. This is important. Because temperature will affect the surface finish and yield of molded parts. All measured values must be recorded and the injection molding machine checked at the specified time.

- 17 Even cooling:The injection molded parts must be cooled uniformly, that is, different parts of the mold must be cooled at different speeds, so that the entire product is cooled uniformly. The injection molded parts must be cooled at the fastest speed, while ensuring that no defects such as uneven surfaces and changes in physical properties occur. The cooling rate of each part of the injection molded part must be equal, but this means that the mold is cooled by a non-uniform method, for example, cold water is fed into the inner core part of the mold, and the outside of the mold is cooled by warm water. This technique should be used when the syringe is molded into a precise straight product or a large product with long melt flow.

- 18 Temperature and cooling check:Be sure to check whether the injection molding machine settings and operating temperature meet the requirements of the record sheet. This is important because temperature affects the surface finish and yield of molded parts. All measured values must be recorded and the injection molding machine checked at the specified time.