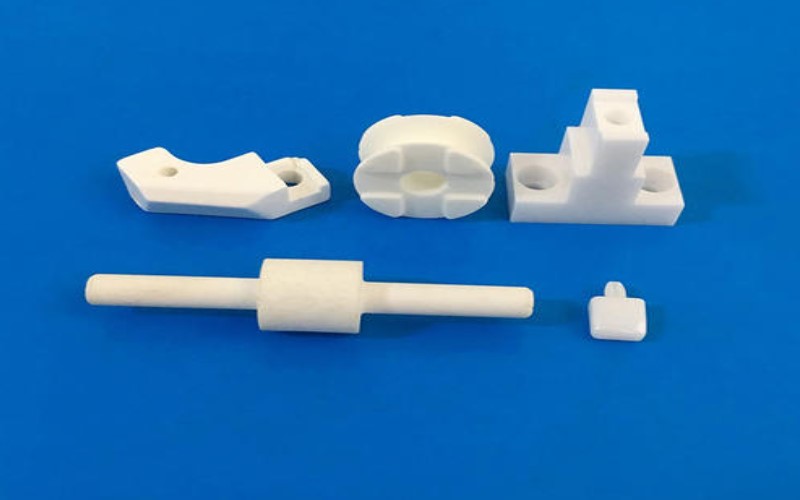

Products for ceramic machining services include ceramic nozzles, ceramic dispensing valves, ceramic rods, ceramic shafts, ceramic pipe rings, ceramic sheets, tungsten steel high-speed probes, tungsten steel valve bodies, etc. Deep hole punching is a punching process when the hole diameter is equal to or less than the thickness of the material to be punched. Blanking Blanking is a stamping process that separates the material along the closed contour. The separated material becomes a workpiece or a process part, most of which is planar. Shrinkage Shrinkage is a type of punching that pressurizes the opening of a hollow part or a tubular part to shrink it. It is a stamper who relies on material flow and changes the shape and size of the process parts in a small amount to ensure the accuracy of the workpiece. Renovation Renovation is to cut a small amount of wood along the outline or inner contour.

Compared with the ZrO material made of SiN full ceramic bearings, it is suitable for higher speeds and load capacities, as well as higher ambient temperatures. At the same time, it can provide precision ceramic bearings for high-speed, high-precision and high-rigidity spindles, with manufacturing precision reaching P to UP level. Full-fill ball Full-fill ball type full ceramic bearing is provided with a notch on one side because of the cage-free structure. It can be loaded with more ceramic balls than bearings with standard structure, so as to improve its load capacity. In addition, it can avoid the limitation of the cage material, and can achieve the corrosion resistance and temperature resistance effect of the ceramic cage type full ceramic bearing. This series of bearings is not suitable for higher speeds. When installing, pay attention to install the notched surface on the end that does not bear axial load. Hybrid ceramic balls are silicon nitride balls with low density, high hardness, low friction coefficient, wear resistance, self-lubrication and good rigidity. They are suitable for rolling elements of high-speed, high-precision and long-life hybrid ceramic ball bearings (inner and outer rings are metal). Generally, bearing steel (GCr) or stainless steel (AIS) is used for the inner and outer rings.