Because of the development of new technology and aluminum templates, especially for injection mold planning, aluminum molds are also increasingly used in platforms such as blow molds, R.I.M. molds, rubber molds, layout foam molds, and R.T.M. molds. Although it may not be applicable to all application platforms, in fact, its application has become more and more widespread. Everyone is expected to be able to extend the production and application life of the mold. For example, the traditional object steel production mold is used, and the surface is hard chromium or nickel metal plating, or the more professional engineering coating is used. Erosion, promote its better demoulding. In the future, in order to pursue the same goal, he began to accept aluminum molds and found a realistic solution.

Bottle cap mold, bottle cap mold plan and process, how to improve the application compliance and group quality of plastic bottle cap mold

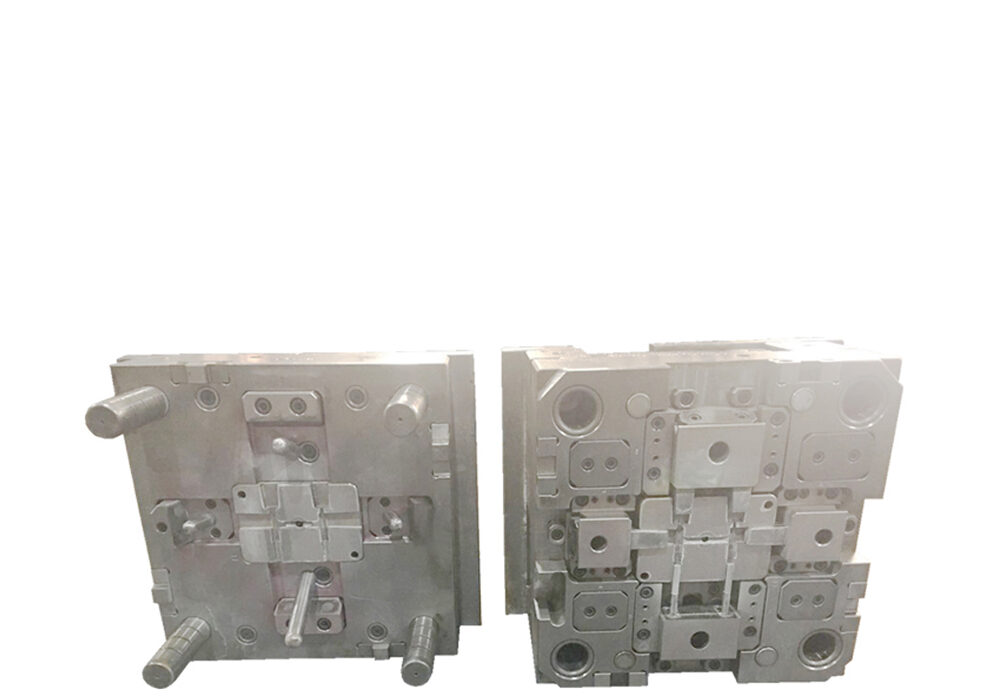

Bottle cap molds, bottle cap mold plans and processes, how to improve the application compliance and group quality of plastic bottle cap molds Today, with China’s economic development, the number of high-precision plastic mold applications is also increasing, and users require plastic mold applications It is also getting higher and higher. This article gives a brief explanation of the plastic bottle cap mold plan, process essentials and common quality issues, and puts forward a few more reasonable management points to improve the application of plastic bottle cap molds, …

In order to be able to produce parts with better decoration by injection molding, in addition to extending the service life of the mold, the manufacturer also hopes that the surface of the aluminum mold can maintain a certain degree of gloss, so it is recommended to adopt electroless nickel spraying process, because This method helps to extend the life of the mold surface finish, making it relatively easy to produce decorative parts.

Because the texture of aluminum is soft, if it does not accept the surface coating, it will be easily worn by the plastic and accelerate its damage, thus changing the gloss of the injection molded parts. The electroless nickel coating can increase the mold surface by 50RC, which is enough to protect and extend the gloss and layout of the mold surface. Electroless nickel coating can achieve better surface finish quality than aluminum itself, but it must be pointed out that a little surface treatment is necessary before the mold can be electroplated. For example, in order to enable it to reach the lens-level quality level, it is recommended to start processing the surface of the aluminum mold to the SPIA-3 level of finish, and then apply 0.0003 ~ 0.0005 high-phosphorus electroless nickel coating before it is further polished. So that it reaches the diamond-quality finish level.

Plastic mold, injection gas affects product quality, breathable mold steel is useful for handling related problems in the plastic mold industry

Plastic mold, injection gas affects product quality, breathable mold steel is useful for dealing with related topics in the plastic mold industry, gas in the plastic mold cavity, and gas odors that occur during the plastic injection process affect the performance, surface and application life of mold products, etc. It is necessary to configure the air pressure in the surface of the mold cavity of the exhaust and air induction system to ensure the smooth production of finished plastic products. New mold technology, R & D and application of new mold technology are the new mold technology in the future …