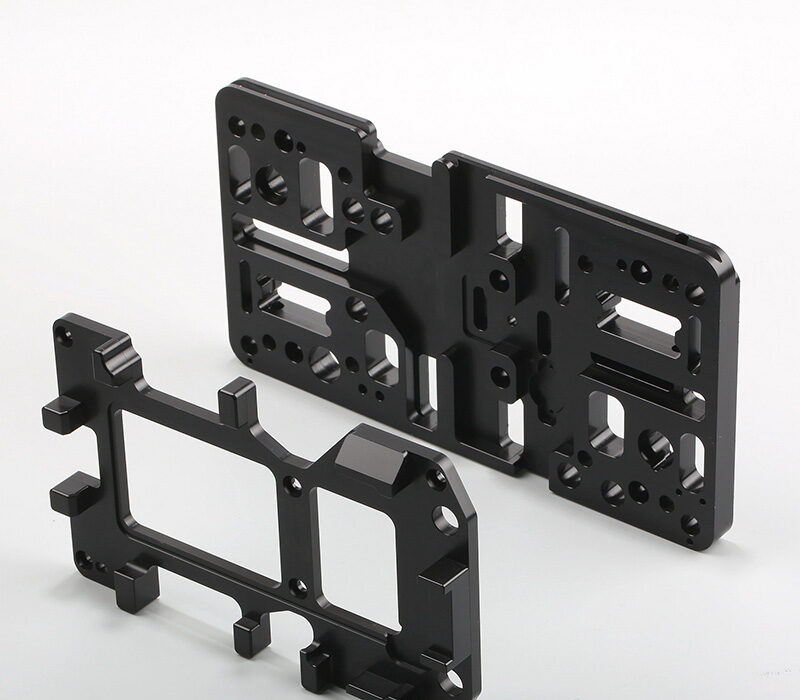

The role of common plastic mold mold base parts

Fixed mold seat plate (panel): fix the front mold on the injection molding machine.

Runner plate (nozzle plate): Remove the waste handle when opening the mold to make it fall off automatically (three plate mold).

Fixed mold fixing plate (A plate): the front mold part of the molded product.

Moving mold fixing plate (B plate): the rear mold part of the molded product.

Cushion: Mold feet, its role is to allow the top board enough space for activity.

Push plate: When the mold is opened, the product is pushed out of the mold through the push rod, top block, inclined top and other push parts.

Moving mold base plate (bottom plate): Fix the rear mold on the injection molding machine.

Guide post and guide sleeve: play the role of guide positioning, assisting the front and rear mold opening mold, and mold and basic positioning.

Supporting column (supporting head): Improve the strength of B board, effectively avoid the deformation of B board caused by long-term production.

Top plate guide post (center support): guide positioning push plate to ensure smooth ejection.

the authorPlastic Mold

All posts byPlastic Mold

You Might Also Like

Balance the “material and shrinkage” of injection molding

Plastic Mold2020年9月6日

The shrinkage rate of the molding material in the injection mold factory has a great influence on the dimensional accuracy...

Poor injection molding problems and solutions

Plastic Mold2020年9月6日

Two months ago, Mr EMAODL in India was troubled by the problem of poor injection molding. Mr EMAODL contacted PTJ...

What are the twists and turns of the plastic mold quotation?

Plastic Mold2020年9月6日

"Seriously, after working with you, I learned that you are so dedicated to making plastic molds." This is Ms. Huang,...

The original intention of the plastic mold processing plant

Plastic Mold2020年9月6日

In Dongguan, there is such a plastic mold processing factory that has been making molds and injection molding shells for...

How to identify the strength of a plastic mold factory

Plastic Mold2020年9月6日

How to identify whether a plastic mold factory's qualifications meet its own psychological standards, PTJ believes: Interlace is like a...