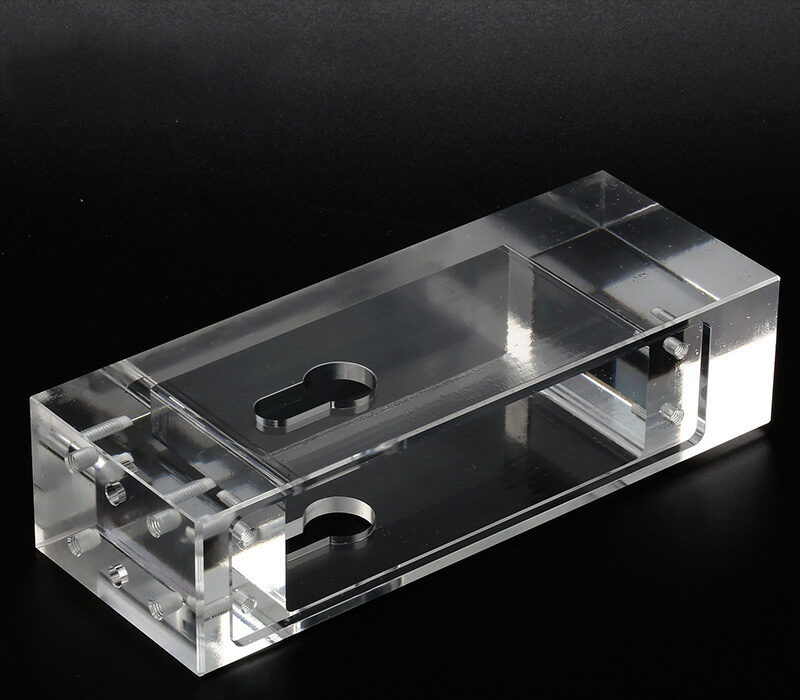

How much do you know about the entire plastic mold processing and design process? The first thing to consider is the finished plastic drawing and the analysis of the actual samples. At this point we have to consider the geometry, size, technical requirements, appearance, tolerance and design basis of the product.

What we have to consider is the model of the injection machine, and what kind of injection molding machine to choose is also a very critical factor.

The determination and arrangement of the number of cavities is also an important process. For example: the weight of the product and the injection volume of the injection machine, the accuracy of the product, whether the product has side cores and the processing method, etc.

Selection of injection mold profiles.

The determination of the mold frame and the selection of standard parts, the design of the mold pouring system, the design of the exhaust system, the design of the cooling system, the design of the thimble system, the design of the guide device, the drawing of the main parts of the mold, the proofreading and design of the design drawings Signing of drawings.

The entire plastic mold processing design process

the authorPlastic Mold

All posts byPlastic Mold

You Might Also Like

The advantages and disadvantages of 3D printing prototype spray paint and UV highlight treatment

Plastic Mold2021年9月26日

In the process of making 3D printing models, some products with high appearance requirements often need to be spray painted...

Factors affecting the price of beryllium copper

Plastic Mold2021年7月28日

International economic situation. The correlation between the commodity market and the economic situation is obvious, especially as the world economy...

How to determine the thickness of aluminum alloy die castings

Plastic Mold2021年7月22日

In the design process of aluminum alloy die castings, many customers are uncertain about the thickness of aluminum alloy die...

Precision CNC machining manufacturers explain how CNC CNC lathes are processed

Plastic Mold2021年7月22日

According to the introduction of precision CNC machining manufacturers, the large-scale CNC machining parts are made of bar materials, and...

Talking about the Application of Beryllium Copper in Plastic Mould

Plastic Mold2021年6月28日

Talking about the Application of Beryllium Copper in Plastic Mould Nowadays, more and more beryllium copper mold materials have...