In order to meet the mold temperature requirements of the injection process, a temperature regulation system is needed to regulate the mold temperature. For injection molds for thermoplastics, the cooling system is mainly designed to cool the mold.

The common method of mold cooling is to set up a cooling water channel in the mold, and use the circulating cooling water to take away the heat of the mold; in addition to the hot water or steam of the cooling water channel, the heating of the mold can also be installed in and around the mold. Heating element.

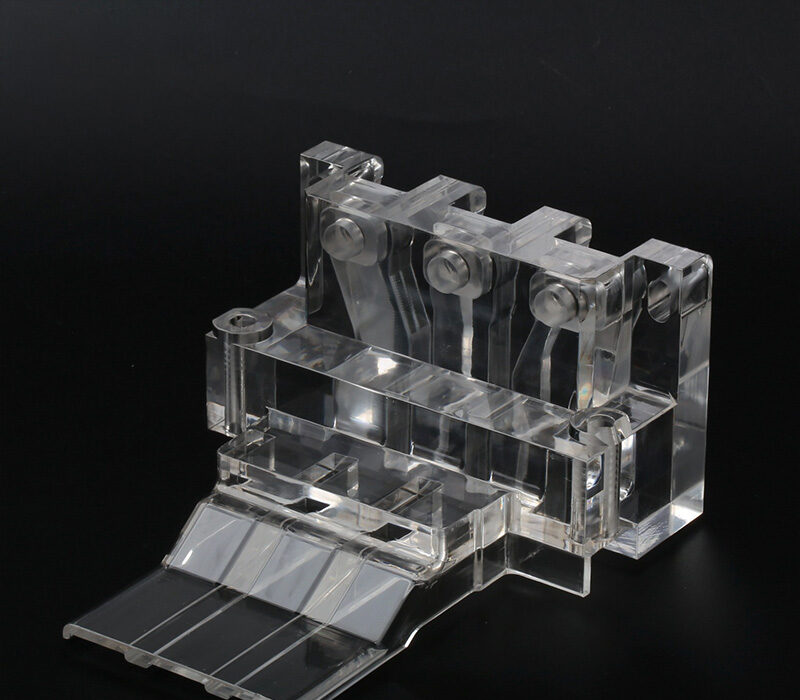

Molded parts refer to various parts that form the shape of the product, including moving mold, fixed mold and cavity, core, molding rod and exhaust port. The molded part consists of a core and a die. The core forms the inner surface of the product, and the concave mold forms the outer surface shape of the product. After the mold is closed, the core and the cavity form the cavity of the mold. According to the process and manufacturing requirements, sometimes the core and die are composed of several pieces, sometimes made as a whole, and inserts are only used in parts that are easily damaged and difficult to process.