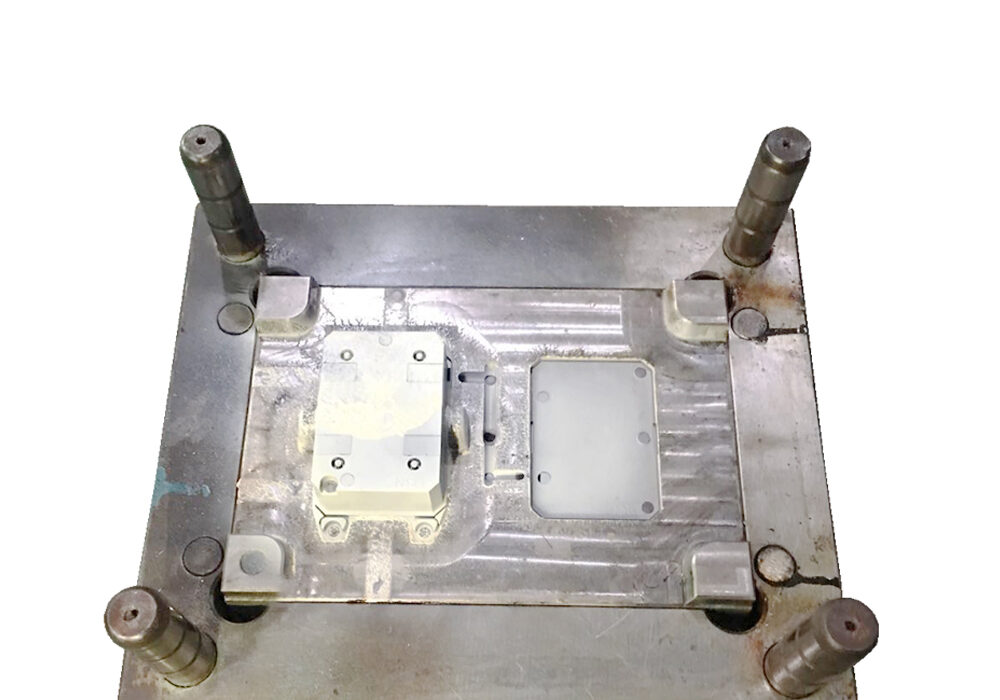

Each plastic mold injection product must first determine the target of the mold opening and the parting line when designing, to ensure that the core pulling mechanism and the elimination of the external impact of the parting line are minimized.

After the purpose of the mold opening standard is set, the structure of the product’s reinforcing ribs, buckles and protrusions should be designed to be consistent with the goal of the mold opening standard as much as possible to avoid core pulling to reduce the stitching line and delay the mold life.

After the target of the mold opening standard is set, the appropriate parting line can be selected to improve the appearance and function.

Demolding slope

Appropriate stripping slope can avoid product pulling. The mold release slope of the smooth mold should be greater than 0.5 degrees, the fine skin pattern should be greater than 1 degree, and the rough skin pattern should be greater than 1.5 degrees.

When designing deep cavity structure products, the external profile slope is required to be less than the internal profile slope to ensure that the mold core is not biased during injection, to obtain an average product wall thickness, and to ensure the material density strength of the product tooth opening.

Product wall thickness

All kinds of plastics have a certain wall thickness scale, generally 0.5 ~ 4mm, when the wall thickness exceeds 4mm, it will cause too long cooling time, shrinkage and other problems, should consider changing the product structure.

Uneven wall thickness will cause the profile to shrink.

Uneven wall thickness can cause porosity and weld marks.

Starting design of plastic mold injection products

the authorPlastic Mold

All posts byPlastic Mold

You Might Also Like

The diversity of CNC prototype model processing methods?

Plastic Mold2021年5月11日

The diversity of CNC prototype model processing methods? Do you know the CNC prototype model? The following Pingte precision hardware...

5 major processing methods of plastic molds

Plastic mold manufacturers know that plastic molds generally fall into five categories, namely: punching and shearing molds, zigzag molds, drawing...

From what aspects can the quality of plastic molds be identified

In daily life, how to distinguish between good and bad plastic mold is indeed a problem, especially when remotely controlling...

Common problems and solutions of plastic mold test

Mold trial is an important step that must be passed after the completion of plastic mold manufacturing. Various problems will...

Measures to prevent damage during plastic mold machining

How to prevent damage during plastic mold machining? To prevent damage, we have to improve our own strength. If there...