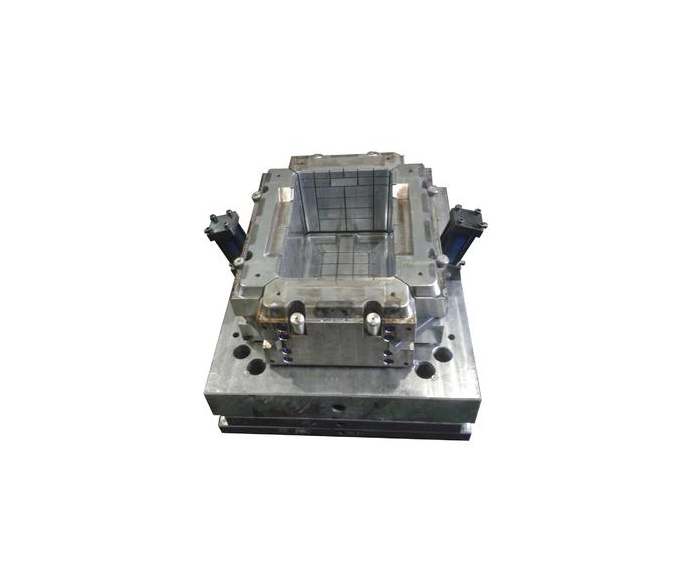

1. Mold pre-inspection

Once the plastic mold is installed on the mold, it should be inspected in order to find quality problems in time, repair the mold to avoid removing it after installing the machine, when the mold fixed template and the moving template are checked separately, pay attention to the direction marks to avoid mold clamping Make a mistake.

2. Inclined guide mode device

When installing the mold, the two should closely cooperate to pay attention to safety. If there is a mold with a lateral parting structure, the slider should be installed in a horizontal position, that is, the movable block moves left and right.

3. Mould fastening

After the mold positioning ring is installed in the positioning ring seat of the fixed template on the injection molding machine, the mold is closed at a very slow speed, so that the moving template gently presses the mold, and then the compression plate is installed. It is necessary to install 4 pieces on the top and bottom of the compression plate. When loading the compression plate, it is necessary to pay attention to adjust the height of the adjustment screw to the same height as the die foot, that is, the compression plate should be flat. If the pressure plate is inclined, the mold foot cannot be pressed tightly. The side of the pressing plate should not be close to the mold to avoid friction damage to the mold.

4. Correct the ejection distance of the top rod

After the mold is tightened, slowly open the mold until the moving template stops retreating. This is because the position of the ejector rod should be adjusted to a gap of not less than 5 mm between the ejector plate on the mold and the bottom plate of the moving mold to avoid The mold is damaged, and the part can be ejected.

V. Adjusting the tightness of closed mold:

In order to avoid overflow, and ensure the proper exhaust of the cavity, when adjusting the hydraulic injection plug-toggle clamping structure, it is mainly based on visual inspection and experience, that is, when the mold is closed, the toggle is fast and then slow, which is not very natural It is not too reluctant to straighten, the tightness of the closed mold is just right. For molds that require mold temperature, the mold tightness should be closed after the mold temperature is increased.

Sixth, connect the cooling water:

After connecting the cooling water, check whether it is dredged or leaking.