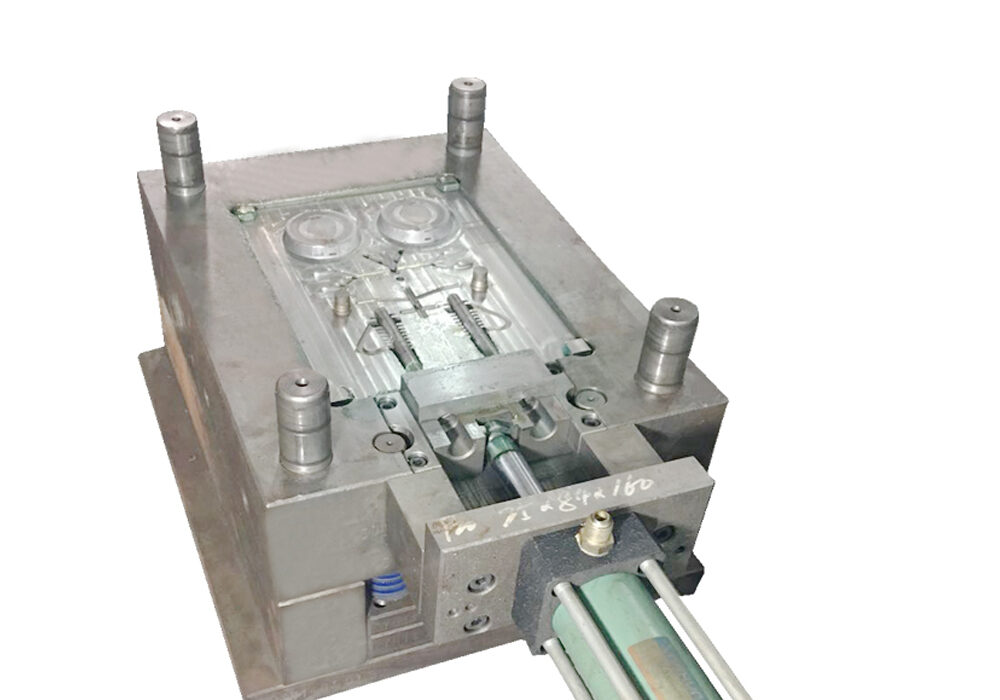

Why is it difficult to demold

- 1) The groove in the mold;

- 2) Insufficient release angle;

- 3) The mold finish is not high.

Failures caused by insufficient mold release slope are very common.When designing products, the mold release slope must be marked on the drawing.The mold release slope usually ranges from 1 to 2 degrees. It is better to be as large as possible. Special occasions are also allowed to be above 0.5 degrees.

If the injection pressure is too high, the product is too close to the mold, and demolding becomes difficult. In order to remove the product from the mold smoothly, a general-purpose mold release agent containing silicone oil is used. However, when using the mold release agent, only a thin layer can be applied. It is difficult to wipe if the spray is too thick. Also, due to the action of the release agent, secondary processing such as printing marks on the product becomes very bad. Once the release agent applied to the mold is attached to the product, it is quite difficult to wipe it off.

Based on the above root causes, come up with a solution:

- 1. Instant: Decrease injection pressure, shorten holding time, lower mold temperature, lower demolding speed, spray mold release agent

- 2. Short-term: Improve the mold cavity finish

- 3. Long-term: increase the stripping slope and increase the number of stripping pins

Heavy and hard materials, such as GPPS, are often damaged due to insufficient de-capping slope. For materials that are both sticky and soft, such as PE, it is possible for the product to be cut off as a number of roots. PVC drain pipe is mainly used for water supply, the diameter of the drain pipe is generally 50-75-110-160 and so on.

The PVC drain pipe is made of hygienic-grade polyvinyl chloride (PVC) resin as the main raw material, added with an appropriate amount of stabilizers, lubricants, fillers, coloring agents, etc., extruded by a plastic extruder and injection molded by an injection molding machine. Curing, shaping, inspection, packaging and other processes to complete the production of pipes and fittings.

PVC drainage pipe is an alternative product of traditional drainage pipes, and has better physical and chemical properties. Its inner wall is smooth and has less frictional resistance than conventional drainage materials, so the installation slope of the horizontal pipe is smaller, which can increase the indoor height of the building. At the same time, the PVC drainage pipe is light in weight and is one-fifth of the cast iron pipe, which is easy to transport and operate; it adopts adhesive connection, which is convenient for installation and maintenance; the price is cheaper than conventional drainage pipes, which greatly reduces the cost of the project; It is widely used in construction sewage and rainwater piping systems.

In addition, the widespread use of PVC drainage pipes is conducive to saving steel, which is of great significance to alleviate the situation of steel shortage in China.