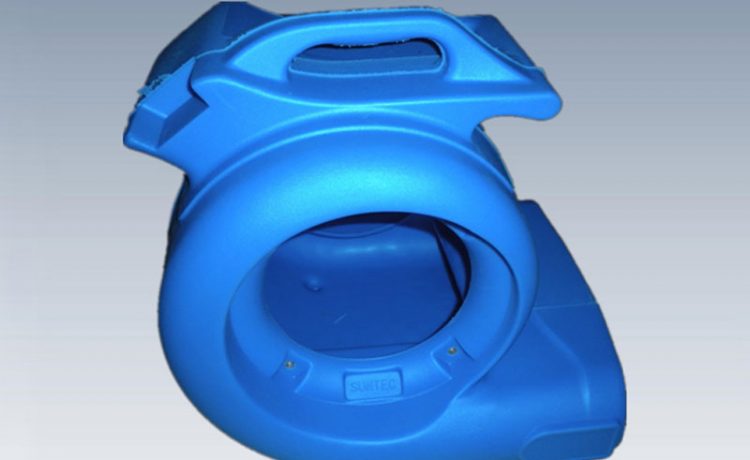

Rotational molding technology

Rotational Moulding, which is to put a certain amount of powdered resin into a cold mold, and the mold is driven by a rotomolding machine to slowly revolve and rotate around two mutually perpendicular rotating shafts. At the same time, the mold is heated by an external heating source, thereby making the resin powder The method of melting and uniformly coating the entire cavity surface of the mold with its own gravity, and finally obtaining a hollow product after cooling and demolding.

Features of the rotomolding process:

- 1. Low cost of rotomolding molds: For products of the same size, the cost of rotomolding molds is about 1/3 to 1/4 of the cost of blow molding and injection molds

- 2. The edge strength of the rotomolded product is good, and the thickness of the rotomolded product can be more than 5 mm, which completely solves the problem of the thinner hollow product;

- 3. Various inserts can be placed in rotomolding;

- 4. The shape of rotomolded products can be very complicated, and the thickness exceeds 5 mm;

- 5. Rotomolding can produce fully enclosed products;

- 6. Rotomolded products can be filled with foam materials to achieve thermal insulation;

- 7. No need to adjust the mold, the wall thickness of the rotomolded product can be adjusted freely (more than 2mm);

- 8. The product is hollow and seamless, but the wall thickness can be adjusted to make the product have high strength;

- 9. Various surface pattern treatments can be provided to produce various color products, which can be used for anti-ultraviolet and anti-aging treatment, and can be used for various stone and wood simulation effects.

Main applications of rotomolding products

With the continuous development of the rotomolding process, the types of rotomolding products continue to increase, and the scope of applications has also continued to expand. At present, the industries involved in rotomolding products at home and abroad include transportation, traffic safety facilities, entertainment, river channel dredging, construction, water treatment, medicine and food, electronics, chemicals, aquaculture, textile printing and dyeing, etc .:

1. Container rotomolding

Such plastic parts are widely used in storage and supply tanks, water storage tanks, various industrial chemical storage and transportation containers, such as acids, alkalis, salts, chemical fertilizers, pesticide storage tanks, chemical enterprises, industrial coatings, rare earths Washing tanks, reaction tanks, turnover boxes, garbage bins, septic tanks, domestic water tanks, etc. in preparation. For example, the rotomolded cross-linked polyethylene drum made by Philips’ rotomolded grade cross-linked polyethylene resin “Maricxcl-100” can be comparable to metal drums, and it has good chemical resistance and low maintenance costs. .

2. Rotomolding parts for transportation

Mainly uses polyethylene and polyvinyl chloride paste resin to rotomold various automotive parts, such as air conditioner elbows, vortex tubes, backrests, armrests, fuel tanks, mudguards, door frames and gear lever covers, battery cases, snowmobile And motorcycle fuel tanks, aircraft fuel tanks, yachts and their water tanks, boats, and shock absorbers between ships and docks.

3. Rotomolding parts of sports equipment, toys and crafts

Mainly include various kinds of PVC paste rotomolding parts, such as water polo, float, small swimming pool, recreational boat and its water tank, bicycle seat cushion, rotomolding pallet, surfboard and so on. Because the rotomolding mold can be manufactured by precision casting, electroforming, etc .; the surface of the rotomolding parts “replicates” the fine structure of the mold cavity surface very well, so the rotomolding method can make the products very delicate and beautiful, so it is commonly used In order to make products with greater ornamental value, especially toys such as ponies, dolls, toy sand boxes, fashion models, crafts, etc.

4. Various types of large or non-standard rotomolded parts

Rotomolding products are widely used in various boxes, shells, large pipes and other parts, such as racks, machine shells, protective covers, lampshades, agricultural sprayers, furniture, canoes, camping vehicle roofs, sports fields Installations, planters, bathrooms, toilets, telephone booths, billboards, chairs, highway barriers, traffic cones, river and sea buoys, anti-collision tubes, and construction barriers, etc.

Our company has customized a variety of rotomolding molds and rotomolding products for customers at home and abroad for a long time. We can open molds according to the drawings or samples provided by customers and design and design.