With the continuous development and improvement of industrial level, plastic products play more and more roles in our lives. As an indispensable tool in the manufacturing industry, injection molds have also developed rapidly in recent years; but many companies often see feedback from injection molding companies .Why is the mold quotation so high? In fact, this is due to many reasons. To understand the high quotation of injection molds, you must first understand the mold injection process.

What is mold injection?

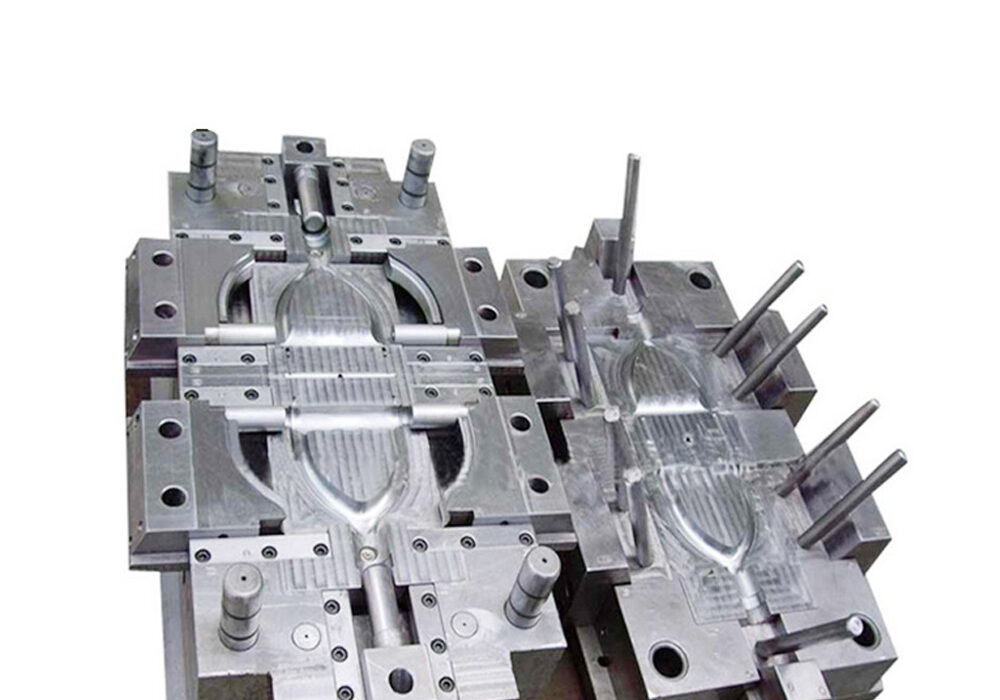

Injection mold is an indispensable tool for producing plastic products in the process of industrialization and mass production. It affects the complete structure and precise size of plastic products. Injection molding is one of the tools used in mass production of plastic products. This processing method specifically refers to injecting a material melted by heat into a mold cavity under high pressure, and cooling and solidifying to obtain a molded product.

Injection molding can achieve one-time molding of plastic products with complex shapes, which is a high-efficiency, large-volume production method, and the quality of injection molding directly affects the quality of injection molding. In the mold industry, if you want to process high-precision, high-quality, complex-surface injection molds, you must use advanced computer-aided design and manufacturing software and compile reasonable processing procedures. This is to ensure processing quality, improve production efficiency, and reduce An effective way of labor intensity.

The following is an analysis of the reasons why injection mold manufacturers have higher prices for injection molds

- 1. It takes a long time to manufacture injection molds. In order to achieve high precision, some plastic mold manufacturers have made molds in this aspect very carefully. Special personnel follow up and strive to make customers satisfied, so the more time required, the more investment Funding will increase accordingly.

- 2. There are many manufacturing processes for injection molds, the cost of purchasing standard parts is high, and the manpower required for complex processes is relatively large. In order to ensure quality, plastic mold manufacturers also need to go through many tests.

- 3. The manufacturing of injection molds is difficult, and the design requirements of injection molds are very high. The main design of the mold runner is accurate, such as the early mold flow analysis. In the case of success, it is very difficult to modify the mold, and most of them need to rebuild the mold.

- 4. The number of mold manufacturing sets depends on the sample. Sometimes it seems that a plastic part with a very simple structure requires two sets of injection molds or even three sets of injection molds to complete the processing. Finally, the price of the injection mold was even calculated to be 100,000 yuan, and it was this high contrast that caused a great psychological impact on the customer.