- 1. Purpose Standards and specifications for the production and processing of hot nozzle holes on the back

- 2. Application area It is more suitable for CNC production and processing department of manufacturing department.

- 3. Features Hole depth, low precision requirements, and avoidance

- 4. Production and processing

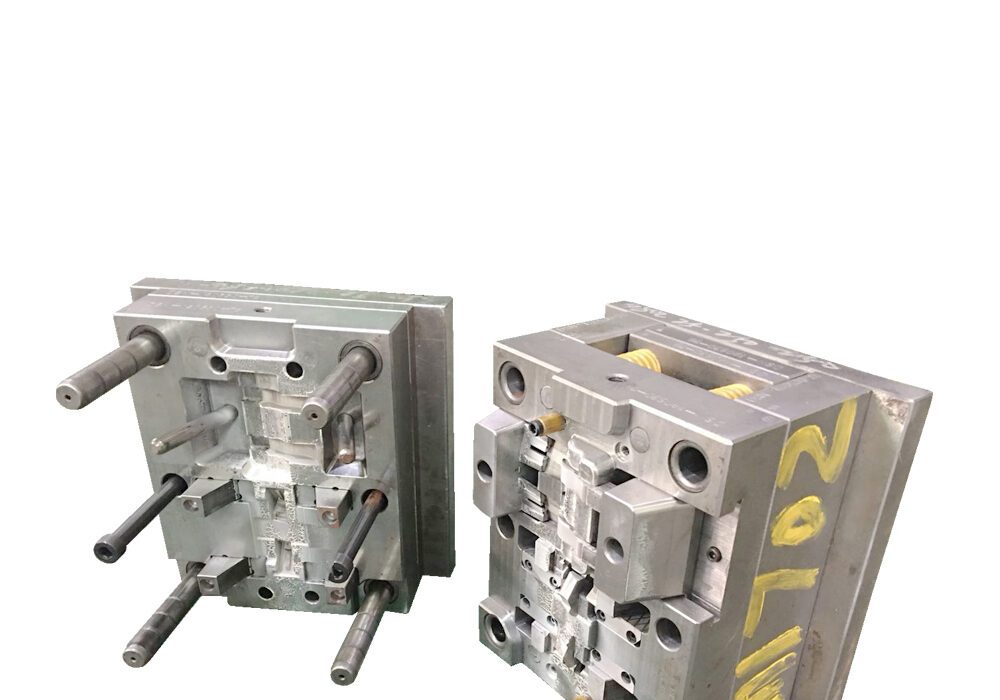

Practical skills in the production and processing of plastic mold hot nozzle holes

- ① Production and processing of gun drilling pilot holes. Special attention: the straight drill of the gun drill can not exceed the straight hole of the matching hole of the front view of the hot nozzle, and the quality is unidirectionally guaranteed. The processing allowance is 2.00 mm.

- ②The production and processing of the gun drill, the water output of the demand management center, the pre-rotation hole for the burst drill, but it can not be connected, leaving 3-5 mm to prevent the cutting oil from flowing down

- ③ Production and processing of explosive drills Water output of Demand Management Center S = 112 F = 5-11

- ④The EDM production and processing of the residue parts is based on the specifications of the hot nozzles and the standard Huaidian-level inventory.

- ⑤ Fillet of mouth.

In daily life, how to distinguish the quality of plastic molds is indeed a problem, especially in the online remote control of market transactions. The key identification barrier is that plastic molds are not like other new products. Other new products have test products. Enterprise customers can also use the test products to assess whether this new product will be the new product they want.

Plastic molds are custom-made. It is the enterprise customer’s requirement to make samples or engineering drawings to the dealers after they have made the molds, and the dealers will produce and process them. In addition to looking at the plastic mold itself, the quality of the plastic mold also depends on whether the new product processed with this mold will be qualified. Generally speaking, there are three aspects to the evaluation of the performance of plastic mold products:

Plastic mould factory

- 1. Appearance quality, including integrity, color, gloss;

- 2. Accuracy between size and relative position, that is, dimensional precision and position precision;

Third, the mechanical properties, chemical properties, electrical properties, etc. corresponding to the use, that is, functionality, therefore, if there is a problem due to any of the above three aspects, it will lead to the occurrence and expansion of plastic mold product defects.