The scrap is essentially the reverse image of the shaped hole. In other words, the same position is in the opposite position. By checking the waste, you can judge whether the gap between the upper and lower dies is correct. If the gap is too large, the scrap will show rough, undulating fractured surfaces and narrow bright band areas.

The larger the gap, the greater the angle formed by the fracture and the larger the bright band area. If the gap is too small, the scrap will show a small-angle fracture surface and a wide bright band area.

Excessive gaps create large curled and torn edges, making the outline slightly protruding and the edges thin. Too small a gap will result in a band that is slightly curled and torn at a large angle, resulting in a section that is more or less perpendicular to the surface of the material. The ideal scrap should have a reasonable crushing angle and a uniform bright band. This keeps the punching pressure to a minimum and creates a clean round hole with minimal burrs. From this perspective, increasing the gap to extend the life of the mold is at the expense of the quality of the finished hole.

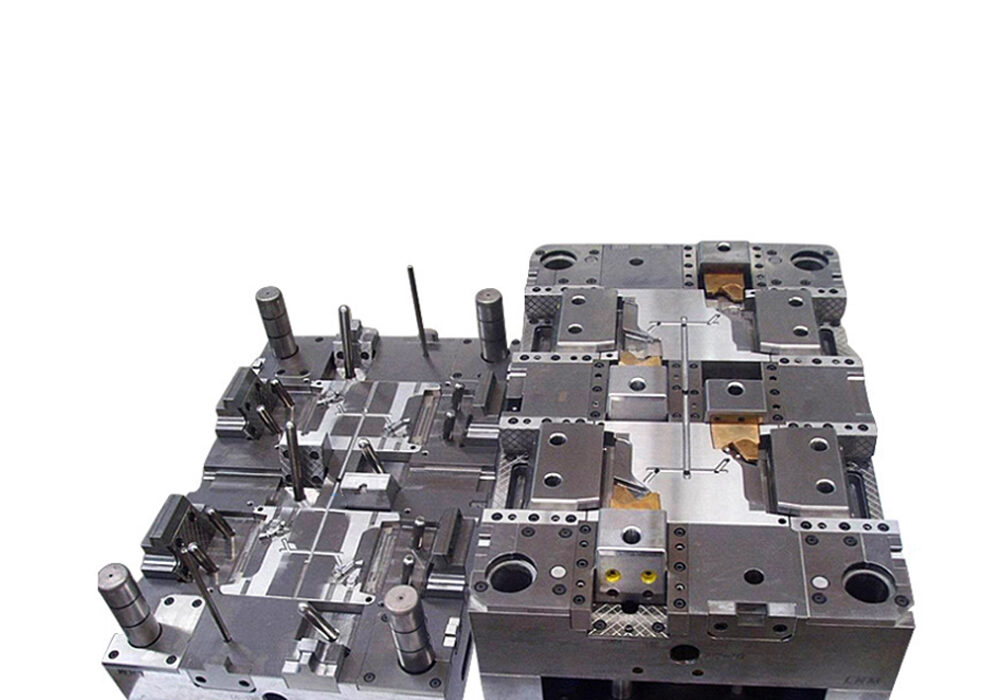

Selection of plastic mold gap

The gap of the die is related to the type and thickness of the stamping material. Unreasonable gaps can cause the following problems:

- (1) If the gap is too large, the burrs of the parts to be stamped are relatively large, and the stamping quality is poor. If the gap is too small, although the punching quality is good, the mold wear is relatively serious, which greatly reduces the service life of the mold and easily causes the punch to break.

- (2) If the gap is too large or too small, it is easy to cause adhesive force on the punching material, thereby generating strips during the punching process. If the gap is too small, a vacuum is easily formed between the bottom surface of the punch and the plate, and the waste material rebounds.

- (3) Reasonable gap can prolong the service life of the mold, have a good discharge effect, reduce burrs and flanging, keep the plate clean, the aperture will not scratch the plate, reduce the number of sharpening times, keep the plate straight Accurate stamping positioning.