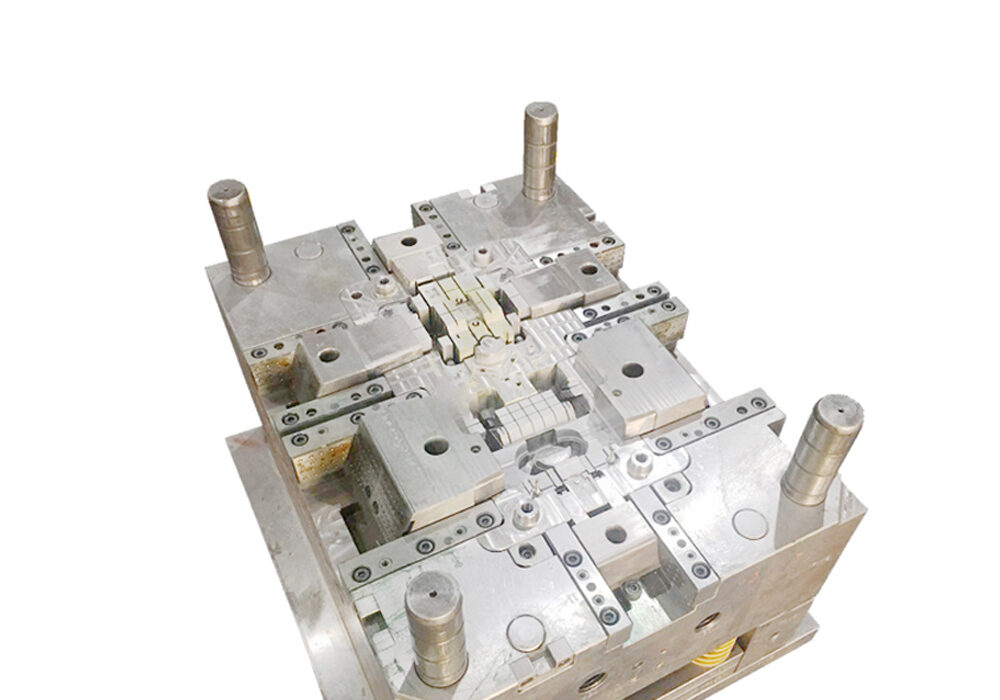

- (1) Large nozzle mold: the runner and gate are on the parting line, and they are demolded together with the product when the mold is opened. The design is the simplest, easy to process, and the cost is low, so many people use the large nozzle system to operate.

- (2) Fine nozzle mold: runner and gate are not on the parting line, generally directly on the product, so it is necessary to design an additional set of nozzle parting line, the design is more complicated, the processing is more difficult, and it is generally selected according to the product requirements Fine nozzle system.

- (3) Hot runner mold: The structure of this type of mold is roughly the same as that of the fine nozzle. The biggest difference is that the runner is located in one or more hot runner plates and hot mouths with constant temperature. The outlet is directly on the product, so the runner does not need to be demolded. This system is also called a waterless system, which can save raw materials. It is suitable for the situation where the raw materials are expensive and the product requirements are high.

Plastic Mold Classification Based On Pouring System

the authorPlastic Mold

All posts byPlastic Mold

You Might Also Like

Balance the “material and shrinkage” of injection molding

Plastic Mold2020年9月6日

The shrinkage rate of the molding material in the injection mold factory has a great influence on the dimensional accuracy...

Poor injection molding problems and solutions

Plastic Mold2020年9月6日

Two months ago, Mr EMAODL in India was troubled by the problem of poor injection molding. Mr EMAODL contacted PTJ...

What are the twists and turns of the plastic mold quotation?

Plastic Mold2020年9月6日

"Seriously, after working with you, I learned that you are so dedicated to making plastic molds." This is Ms. Huang,...

The original intention of the plastic mold processing plant

Plastic Mold2020年9月6日

In Dongguan, there is such a plastic mold processing factory that has been making molds and injection molding shells for...

How to identify the strength of a plastic mold factory

Plastic Mold2020年9月6日

How to identify whether a plastic mold factory's qualifications meet its own psychological standards, PTJ believes: Interlace is like a...