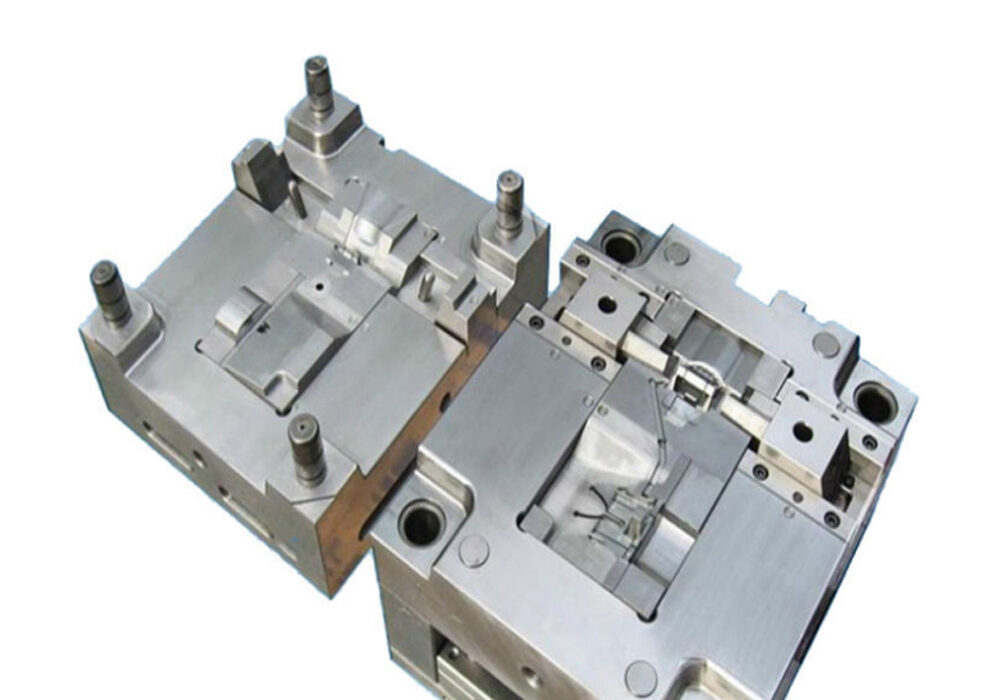

The basic structure of the open mold injection slope roof

Guide block: Since the material is mostly bronze, more places are called bronze guide blocks. When the inclined top is long, position and guide!

Inclined top seat: Due to the convenience of processing and installation, the length of the inclined top can be shortened. The method of the inclined top seat is the most common way to connect the inclined top and the top material plate.

Inclined roof materials and preparation

The choice of sloping top material is to prevent friction and burning during the movement. Generally choose materials with different hardness, or the hardness of the same material is different. The commonly used material for inclined roof is ftc 8407. The guide block is often used for Cr12, beryllium copper, P20 inclined top seat.

The same set of molds should be as steep as possible, with the same angle of the inclined top, so that it is easy to prepare materials. If the milling machine is rough, the grinder is processed separately, the material is fixed separately, and the surrounding enlargement is 2 mm. Integers can be used. As shown in the figure below, set together.

Generally speaking, when we make molds, sometimes the local position of the product is very high or low. We will hollow out a piece and fill it with other materials. If it is too high, the thickness of the mold can save a material, too low or can not be processed, making an insert can be easily processed, the following summarizes when you need to make an insert, when you do not need to make an insert , I hope you can give your opinion, please point out the shortcomings.

- 1 In what circumstances do you need to insert:

- 1.1 Save material. The setting of the back mold is determined by the highest point. If only one shape is taller, you can set a short spot.

- 1.2 Convenient processing. Among the processing equipment, EDM has the slowest speed and the worst accuracy, so sometimes in order to avoid EDM, EDM will be selected as a plug-in.

- 1.3 Easy to exhaust. Especially in some bone deep parts, the discharge of electrical discharge machining is not smooth, and the ventilation is not smooth when molding, often requiring the use of blades.

- 1.4 Guarantee accuracy. The grinder is the most accurate in mechanical processing. Sometimes, in order to ensure accuracy, the grinder will be convenient.

- 1.5 Interchange requirements. Sometimes customers require the same product, such as changing the label position to make interchangeable inserts.

- 1.6 Convenient type. Some positions are deeper and the model is more inconvenient, so they are made into plug-ins.

- 1.7 Easy mold change. Some parts are easy to wear or the accuracy is too high. In order to modify the mold, inserts were made.

- 1.8 Thermal considerations. This mainly refers to beryllium copper blades.

- 1.9 Processing efficiency. Some large molds are small pieces and processed separately to save time.

- 2 Inserts and blind inserts: For some smaller inserts, the Y-shaped cutout and the hanging platform can be used for positioning. For some larger inserts, such as 60×60 or larger, you can take the form of a blind insert and hang the crepe. Processing is more difficult, but the strength of the mold is guaranteed.