In the heat treatment process, precision mold processing often produces deformation. In order to prevent this bad phenomenon, as long as it grasps its deformation law, analyzes the reasons for its occurrence, and adopts different methods to prevent mold deformation, it can be reduced and can controlling. Generally speaking, the following methods can be used to prevent heat treatment deformation of precision and complex molds.

- 1. Fair selection. For precision and complex molds, choose good-quality micro-deformable mold steel (such as air-quenched steel), and mold steel with severe carbide segregation should be reasonably cast and carried out.Solid solution double refinement heat treatment can be performed for larger and uncast mold steel .

- 2. The mold structure design should be fair, the thickness should not be too wide, and the shape should be symmetrical. For the mold with large deformation, the deformation rule should be grasped, and the processing allowance should be reserved. For large, precise and complex molds, a combined structure can be used.

- 3. Precise and complex molds should be pre-heat-treated to eliminate the residual stress generated during the machining process.

- 4. Reasonably select the heating temperature and control the heating speed. For precision and complex molds, slow heating, preheating and other balanced heating methods can be used to reduce mold heat treatment deformation.

- 5. Under the condition of ensuring the hardness of the mold, try to adopt the pre-cooling, stepped cooling quenching or warm quenching process.

- 6. For precise and complex molds, as far as possible, vacuum heating quenching and cryogenic treatment after quenching are used as much as possible.

- 7. For some sophisticated molds, pre-heat treatment, aging heat treatment, tempering and nitridation heat treatment can be used to control the precision of the mold.

- 8. When repairing defects such as die blisters, blowholes, wear, etc., use cold welding machines and other repair equipment with small thermal impact to avoid deformation during the repair process.

There are many methods for the heat treatment process operation, including such as plugging holes, binding holes, mechanical fixing, appropriate heating methods, accurate selection of the cooling direction of the mold and the direction of movement in the cooling medium, etc.The reasonable tempering heat treatment process also reduces precision and complexity Effective measures for mold deformation.

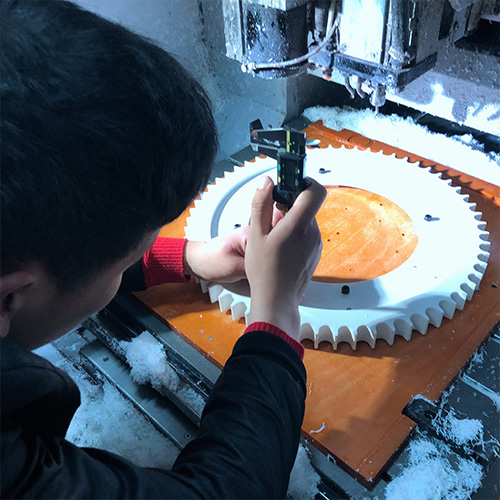

Reasonable arrangement of stamping die manufacturing process and guarantee processing accuracy. The machining accuracy of stamping die has a great influence on the durability of stamping die. For example, due to the uneven assembly gap in the punching die, the die will often be damaged by the shear force and affect the life of the stamping die. At the same time, the surface finish of the stamping die is too low, which also reduces the durability of the stamping die. Therefore, we must pay full attention to the size of the hole pitch, the perpendicularity of the punch to the support surface of the fixed plate during assembly, the uniformity of the stamping die spacing, and the guide accuracy level of the guide sleeve and guide post. The higher the manufacturing and assembly accuracy and the higher the surface roughness level of the working part, the higher the durability of the stamping die.

Our company is a modern private enterprise that integrates product development and design, plastic mold, precision mold processing and manufacturing, product injection, oil injection screen printing, and electronic assembly. It is located on Bihu Avenue, Fenggang, Dongguan City, with convenient transportation. We mainly produce all kinds of precision plastics such as household appliances, digital, communication, office, computers, network and so on. Through cooperation with different customer cases with different requirements, different types of hot runner systems are used to manufacture and manufacture molds, while vigorously developing ultra-precision molds, IMD / IML and other cutting-edge technologies to increase the company’s technological competitive advantage. It is PHILIPS, Toshiba, Hitachi, etc. The remote control series mainly include ASUS, Haier, Helian, Wanshiyi, etc., and there are other office equipment product series.