In recent years, in the plastics process, a popular molding method is rotomolding. Rotational molding, also known as rotomolding, rotary molding, rotary molding, etc., is a thermoplastic hollow molding method.

Rotomoulding originated in the United Kingdom in the 1940s. The first rotomolding patent came out in 1887, and the first commercial rotomolding machine was manufactured in 1934. At first, it was only used as a supplement to injection molding, blow molding, and extrusion. With the maturation of polyethylene powder technology, it has become an extremely competitive molding method in the plastic molding process.

In recent years, in developed countries in North America and Europe, the rotomolding industry has developed rapidly, and its development speed is higher than the average development speed of the entire plastics industry. And the development of the entire rotomolding industry is relatively complete. In addition to rotomolding machine manufacturers and rotomolding product production plants, there are a considerable number of other professional auxiliary factories, such as rotomolding mold manufacturing plants, mold release agent production plants, and rotomolding special Pigment production plant, milling machine manufacturing plant, insert manufacturing plant, and mixing equipment manufacturing plant suitable for rotomolding, as well as many special raw material supply plants for rotomolding, etc

PE bucket made by rotomolding process

Generally speaking, the markets of the United States, Europe and Australia are relatively mature, but new products and new technologies still bring new growth opportunities to the rotomolding industry. The high quality of new equipment products and fast production speeds still drive investment in new production lines and processing. Production shifted to low-cost countries. The developing countries are dominated by low-end products such as water tanks and storage tanks, and their development speed and grade are constrained by the overall industrial foundation level. China is developing rapidly, and Asian countries such as India, Malaysia, Thailand, and Vietnam are also showing good development trends.

China’s rotomolding market

The research and development of rotomolding technology in China started in the 1960s and started late. In the mid and late 1990s, some domestic enterprises introduced advanced rotomolding equipment and technology from abroad, and then began large-scale industrial production in a true sense. But compared with the advanced level of foreign developed countries, the gap is still very obvious, which should be reflected in: backward basic research, poor equipment control capabilities, backward technology, insufficient diversity of rotomolding products.

According to statistics, there are more than 1,500 rotomolded products companies in China; and in the early 1970s, there were more than 500 companies engaged in the production of rotomolded products, with over 500 rotomolding machines. There are more than 5000 kinds of rotomolded products.

In terms of rotomolding raw materials, PE is the main component of rotomolding products in China. The materials used for rotomolding abroad include nylon, PP, PC, ABS and many others.

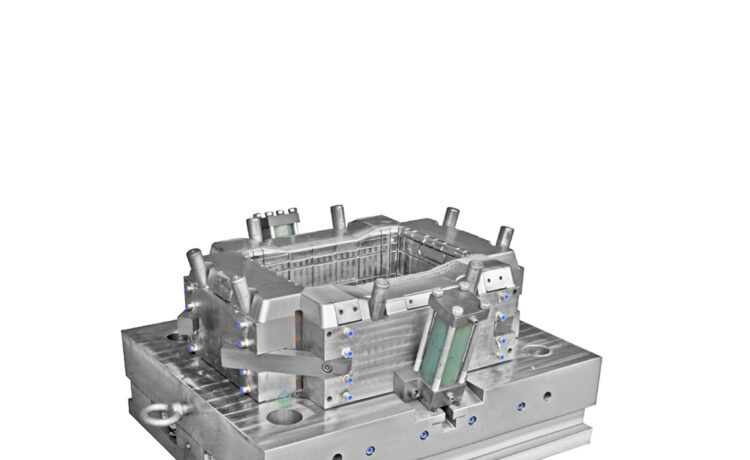

However, after more than 20 years of development, China’s rotomolding process has basically matured, and it has obvious advantages in distinguishing it from other processes. At present, it has been equipped with the modern production of processing large-scale hollow plastic products and special plastic products, the application fields are constantly expanding, and the rotomolding industry has made great progress. It should be said that the rotomolding industry has formed a complete industrial chain for the application of raw materials, equipment, molds and products.

Rotomolding technology has strong vitality and is a process that deserves high attention. The rotomolding process should be highly valued and the rotomolding process should be used to produce various cost-effective plastic parts. Actively digest and absorb advanced foreign technology, and increase research on related processes, equipment and molds.