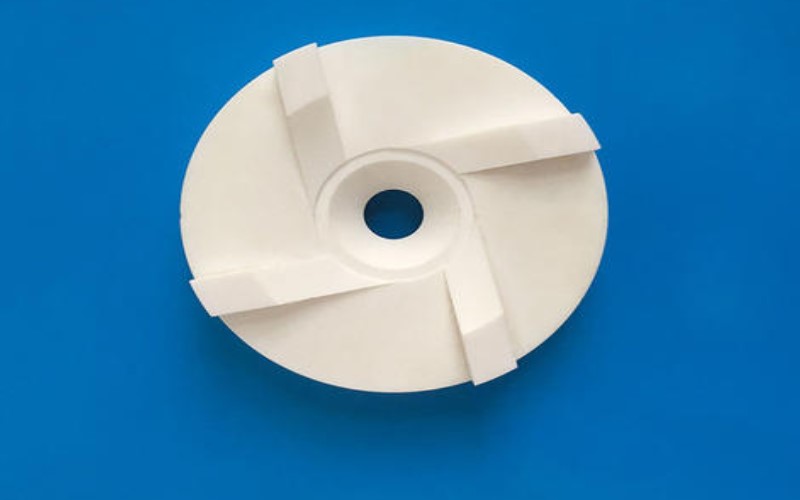

Pay attention to the impact when machining ceramic parts, so as not to damage the ceramic parts in the pump. The removed parts should be handled with care. At the same time, care should be taken to avoid the roughness of the broken seal surface. The use temperature is lower than ℃ (the use of engineering plastic impellers) The temperature depends on the material and medium). The welding process of ceramic suction cup is silver welding. When drilling ceramic chuck materials, the diamond grinding wheel uses high-speed diamond abrasive particles to cut the material. Grinding and polishing certain collars in industrial production. Grinding alone does not meet the surface finish requirements of ceramic chucks, usually grinding and polishing. On the other hand, the ceramic chuck material has less toughness and greater brittleness, and its strength is easily affected by surface cracks. The rougher the processed surface, the sharper the temperature difference is less than ℃. Widely used in mining, smelting, petroleum, chemical industry, dyes and other industries. Recently, in the wet smelting industry, ultra-high molecular weight polymer pumps have poor high-temperature wear resistance, ceramic lined pumps are easy to crack and damage, and high wear-resistant metal alloy pumps are expensive.

China Mold > Blog > 未分类 > Ceramic Chip Ceramic Precision Parts Machining

You Might Also Like

Which factors affect the excellent electroplating quality of zinc alloy die castings?

Plastic Mold2021年6月29日

For zinc alloy die castings to be electroplated surface treatment, this link is very important. If the electroplating is not...

Advantages of ABS plastic hand plate

1. As one of the most widely used plastics, ABS has good impact resistance, heat resistance, low temperature resistance, and...

Application of UHMWPE

As UHMWPE has many excellent properties, it has shown great advantages in the high-performance fiber market, including from offshore oilfield...

Features of Teflon Spray Machining

Teflon spraying process brings the benefits of the surface of the working parts. To a certain extent, Teflon spraying brings...

Application of PPS

Because PPS has good heat resistance, excellent mechanical properties, and good chemical stability and water resistance., PPS processed products are...