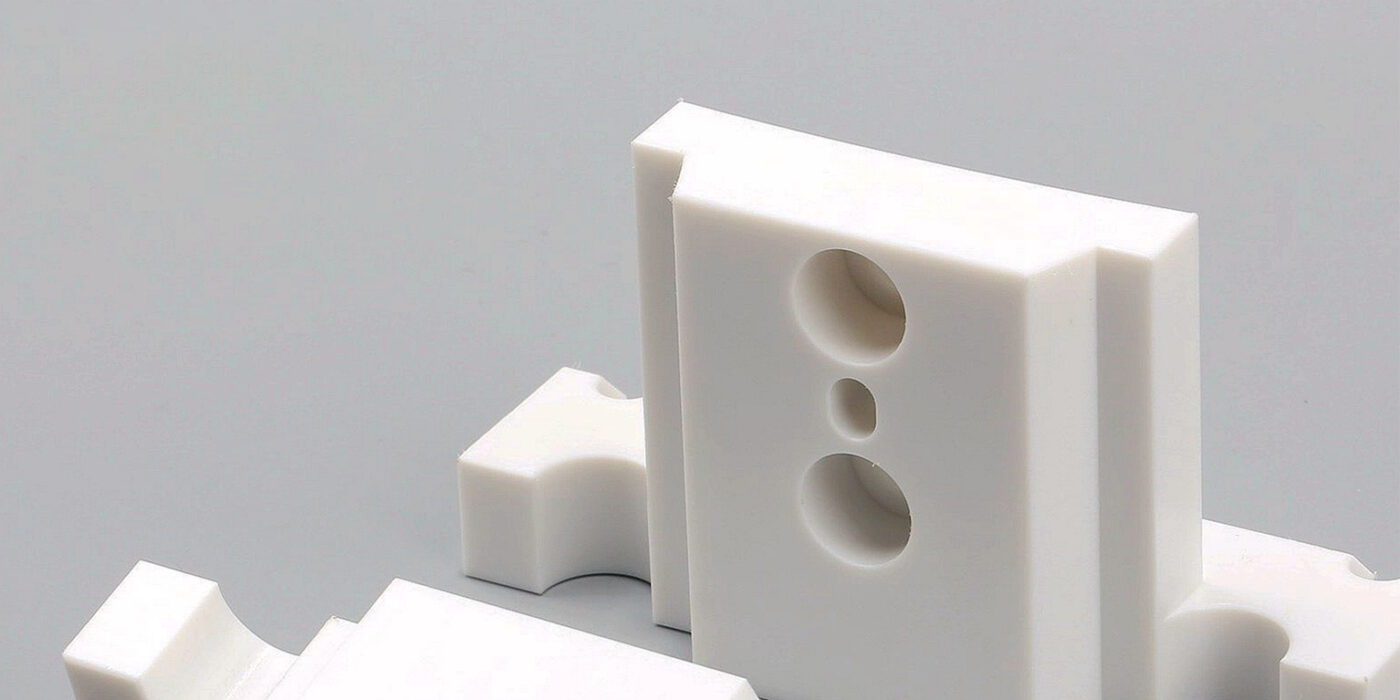

- (1) High processing accuracy requirements A pair of molds are generally composed of concave molds, convex molds and mold frames, and some may also be multi-piece assembly modules. Therefore, the combination of the upper and lower molds, the combination of the insert block and the cavity, and the combination between the modules require high processing accuracy. The dimensional accuracy of precision molds often reaches the μm level.

- (2) Complex shape and surface Some products, such as automobile coverings, aircraft parts, toys, and household appliances, have a curved surface composed of various curved surfaces. Therefore, the mold cavity surface is very complicated. Some surfaces must be processed with mathematical calculations.

- (3) Small batches The production of molds is not batch production in large batches, and in many cases only one production is often paid.

- (4) Multiple processes Various processes such as milling, boring, drilling, reaming and tapping are always used in mold processing.

- (5) Repeatable production The use of molds has a long life. When the use of a set of molds exceeds its life, new molds must be replaced, so the production of molds is often repetitive.

- (6) Copy processing In mold production, sometimes there are neither drawings nor data, and copy processing is carried out according to the actual product. This requires high copy accuracy and no deformation.

- (7) The mold material is excellent and the hardness is high. The main material of the mold is mostly made of high-quality alloy steel, especially the mold with a long life, and it is often made of Crl2, CrWMn and other laisite steel. This type of steel has strict requirements from rough forging, processing to heat treatment. Therefore, the preparation of processing technology can not be ignored, and heat treatment deformation is also a problem that needs to be taken seriously in processing.

According to the above-mentioned many characteristics, the machine tool should meet the processing requirements as much as possible. For example, the functions of the CNC system are stronger, the precision of the machine tool is higher, the rigidity is better, the thermal stability is better, and the copy function is provided.